Introduction to Root Cause Analysis

Root Cause Analysis (RCA) is like a detective’s method for figuring out what really caused a problem or incident, especially in the construction world. It’s super important because it helps us dig deep and really understand what’s going on, so we can fix things properly, not just patch them up. In an industry where safety, efficiency, and cost-effectiveness are paramount, the implementation of RCA can lead to significant improvements in operational performance.

The construction sector, notorious for its complexities, often faces a multitude of challenges ranging from project delays and budget overruns to safety hazards and quality control issues. RCA provides a framework to dissect these challenges effectively, allowing teams to pinpoint the real contributors to problems. By focusing on systemic changes rather than placing blame on individuals, RCA fosters a culture of continuous improvement and accountability.

Furthermore, the importance of RCA extends beyond immediate problem-solving. By uncovering root causes, construction companies can implement sustainable solutions that prevent recurrence of similar issues in the future. This proactive approach not only enhances project outcomes but also contributes to significant cost savings over time. The reduction of repetitive problems translates to improved resource allocation and minimizes wastage, benefiting both the financial health of a construction firm and its overall productivity.

Plus, the impact of RCA on boosting safety standards is truly significant! Identifying the root causes of accidents or near-misses is vital for establishing robust safety protocols and fostering a safer working environment. In this light, root cause analysis serves as a vital tool for mitigating risks and ensuring the welfare of all personnel involved in construction tasks.

Through this lens, RCA emerges as an indispensable practice in the construction industry, as it not only addresses current challenges but also sets the foundation for sustainable growth and improvement.

Common Issues Faced in Construction Projects

The construction industry is fraught with numerous challenges that can significantly impact project outcomes. One of the most prevalent issues is delays, which can arise from various factors such as inclement weather, labor shortages, and changes in project specifications. If a key project component gets stuck due to supply chain issues, other tasks may be delayed, causing a ripple effect and disrupting the project schedule. Such delays not only frustrate stakeholders but can also result in increased labor costs and missed deadlines.

Another common problem is budget overruns. Many construction projects fail to remain within their initially allocated budgets, often due to unforeseen costs or poor initial estimates. Unexpected geological conditions during foundation excavation can lead to additional expenses for specialized equipment or labor. These budget overruns can strain relationships among contractors, clients, and investors and may ultimately lead to serious financial consequences for all parties involved.

Safety incidents are also a critical concern within the construction sector. Construction sites are inherently dangerous, and incidents such as falls, equipment malfunctions, or exposure to hazardous materials can occur. These events not only endanger workers but can also lead to costly legal disputes and project delays. For instance, if a worker sustains an injury on-site, the investigation and safety protocol implementations can halt progress and escalate costs.

Furthermore, quality control issues are prevalent in construction projects. Inadequate attention to quality can lead to subpar workmanship and materials, resulting in structural problems that may require costly repairs or even necessitate complete reconstruction. All these issues emphasize the importance of implementing thorough root cause analysis procedures to identify and mitigate underlying problems, ensuring smoother project execution and enhanced stakeholder satisfaction.

The Importance of Identifying the Root Cause

In the construction industry, the complexities inherent in projects can often lead to various challenges, including safety incidents, budget overruns, and project delays. Addressing these issues typically involves a quick response, often aiming to mitigate the symptoms rather than tackling their underlying origins. However, identifying the root cause of problems is crucial for achieving lasting solutions. This approach, known as root cause analysis (RCA), emphasizes understanding the contributing factors that lead to undesirable outcomes.

Focusing on root causes allows project managers and stakeholders to understand better the systemic issues that lead to problems. When symptoms are treated without knowledge of their origins, the same issues are likely to arise repeatedly, resulting in increased costs and diminished project quality. Conversely, uncovering the root cause equips teams with the necessary insights to develop sustainable solutions that not only address the immediate problem but also prevent future occurrences.

Moreover, the long-term benefits of conducting thorough root cause analysis are substantial. By investing time and resources to identify true causative factors, construction firms can enhance overall efficiency, improve project outcomes, and establish a culture of continuous improvement. This proactive approach ensures effective safety protocols, compliance with industry standards, and maximized workforce productivity. It also creates accountability within teams by clarifying responsibilities when the origins of issues are understood.

In summary, recognizing the significance of root cause identification in construction projects is essential for driving sustainable improvements. By moving beyond a superficial understanding of issues and addressing their fundamental causes, stakeholders can foster a robust framework for enhanced efficiency and effectiveness within the industry. Thus, RCA stands as a vital practice for any organization aiming to succeed in the dynamic landscape of construction.

Step-by-Step Process of Root Cause Analysis

Conducting a successful root cause analysis (RCA) in the construction industry involves a structured approach that can help identify underlying problems, ensuring the implementation of effective solutions. The process typically begins with accurately identifying the problem. It is essential to describe the issue in clear terms, as this lays the foundation for subsequent steps. Field observations, safety reports, and project timelines may be utilized to articulate the problem fully.

Collect the Data

Once the problem has been identified, the next step is to gather data related to the incident or issue at hand. This data can include work documents, interviews with personnel involved, and measurements of physical conditions. Collecting sufficient evidence will facilitate a comprehensive understanding of the surrounding circumstances and may reveal patterns or contributory factors.

Analyze

After data collection, the analysis phase commences. This involves examining the gathered information to discern trends and correlations. Utilizing tools such as the fishbone diagram or the Five Whys can facilitate exploring the various dimensions of the problem, leading to a more informed understanding of potential root causes.

Identify Root Causes

Identifying potential root causes is critical in the RCA process. Collaborating with team members involved in the project can yield diverse insights, increasing the likelihood of pinpointing the actual cause of the issues encountered. Once a list of potential root causes is established, the focus shifts to evaluating these causes to choose the most likely one. This may involve prioritizing root causes based on their impact and frequency, thus filtering out less significant factors.

Implement Corrective Actions

Upon identifying the most likely root cause, the final step involves implementing corrective actions. Developing a plan that outlines specific measures will help mitigate the identified problem and prevent its recurrence. Continuous monitoring and adjustments should follow to analyze the effectiveness of these actions. This methodical RCA process is essential in promoting a safer and more efficient construction environment.

Methods for Conducting Root Cause Analysis

Root cause analysis (RCA) is an essential process in the construction industry, aiming to identify the underlying reasons for issues that arise during projects. Understanding these root causes allows organizations to implement effective solutions and prevent future occurrences. When it comes to conducting a Root Cause Analysis (RCA), there are a bunch of different methods you can use, each with its own cool perks that work best for different situations in construction.

5 Why’s

The 5 Whys technique is like peeling back layers of an onion, asking “why” five times in a row, until you get to the heart of the matter and find out what’s really going on. This straightforward, yet powerful method encourages teams to dig deeper into issues, fostering a culture of critical thinking. In construction, this could be particularly useful in addressing recurring problems on-site, such as project delays. By identifying the root causes, stakeholders can develop targeted intervention strategies.

Tools for Analysis

The Fishbone Diagram, also known as the Ishikawa Diagram, organizes potential causes of a problem into categories, offering a visual representation of various factors that may contribute to an issue. This method is especially beneficial in complex construction scenarios, where multiple variables often interplay. For instance, when analyzing safety incidents, the diagram helps structure thoughts around people, processes, materials, and equipment, enhancing team collaboration in problem-solving.

Fault Tree Analysis is another systematic approach that uses a top-down method to evaluate potential failures in a process. It begins with a specific undesirable event and identifies the pathways through which that event may occur, allowing teams in construction to assess risks comprehensively. This approach is particularly valuable for projects with high stakes, where understanding intricate failure mechanisms is critical.

Finally, Pareto Analysis utilizes the 80/20 rule to focus on the most significant causes of problems. In the context of construction, this method helps prioritize issues by identifying which ones, if addressed, would yield the most significant improvements. By concentrating on critical areas, companies can allocate resources effectively, ensuring maximum efficiency and cost-effectiveness.

These various methods for conducting root cause analysis offer construction professionals powerful tools to uncover and resolve problems, ultimately leading to enhanced project outcomes and safety standards.

Applying the Fishbone Diagram: A Live Example

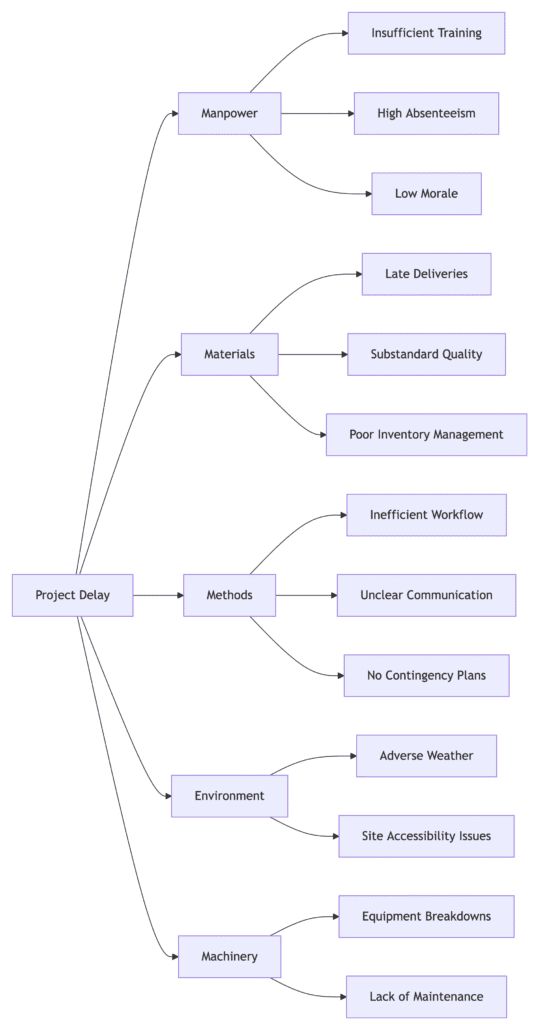

The Fishbone Diagram, also known as the Ishikawa or cause-and-effect diagram, serves as an effective visual tool in root cause analysis (RCA) within the construction sector. Let’s think about a real-life example from building a commercial space. Imagine a time when things didn’t go as planned, and there were some unexpected delays. These setbacks not only increased project costs but also raised concerns among stakeholders regarding timelines and resource allocation.

Analysis

To tackle this, we put together a team to dive deep into the issue with a Fishbone Diagram. We pinpointed the main problem as “Project Delay.” Then, we broke it down into big categories to look at what might be causing it, like Manpower, Materials, Method, and Environment. Under the Manpower category, team members identified factors such as insufficient workforce training and absenteeism. In the Materials category, delays in supply deliveries and substandard product quality were noted. Methodical examination of the methods revealed procedural shortcomings, such as lack of clear communication and inefficient workflow planning. Lastly, environmental factors included adverse weather conditions that impacted construction schedules.

Each of these categories was further dissected to pinpoint specific causes. For instance, the issue of absenteeism stemmed from a lack of proper contingency planning or worker motivation, while supply chain delays were attributed to unreliable suppliers and improper inventory management. Once the causes were categorized, the team prioritized implementing corrective actions based on their potential impact on project timelines.

The Fishbone Diagram thus transformed the way the problem was understood, offering a structured approach to identifying contributory factors leading to the project delay. This detailed analysis facilitated discussions regarding solutions, emphasizing the importance of addressing both systemic and individual factors in the construction process. Through the practical implementation of the Fishbone Diagram, teams can effectively unravel complex issues, ultimately paving the way for enhanced project performance and minimized disruptions.

Case Study: Successful Implementation of RCA in Construction

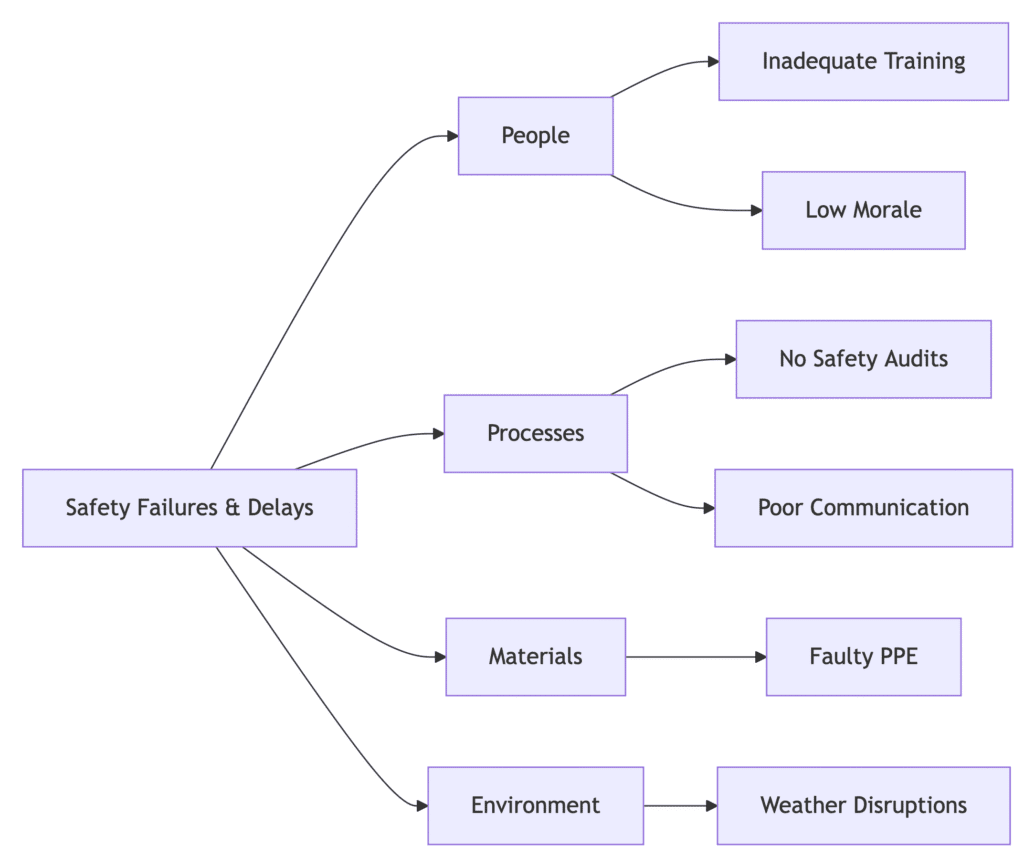

The construction industry often encounters various challenges, ranging from project delays to safety concerns. A notable case study that exemplifies the successful implementation of Root Cause Analysis (RCA) occurred during the construction of the Silver Oak High-Rise Project in 2021. Initially, the project faced significant delays due to repeated failures in meeting safety regulations, resulting in costly downtime and a deteriorating workforce morale.

To address these issues, the project management team undertook a comprehensive RCA process. This involved assembling a cross-functional team composed of project managers, engineers, safety officers, and workforce representatives. The first step was to identify the primary problems and their contributing factors. They discovered that inadequate training, insufficient safety audits, and miscommunication between departments were significant contributors to the delays.

The team utilized a structured RCA framework to dig deeper into these issues. They conducted interviews, gathered data from incident reports, and held brainstorming sessions to understand the underlying root causes. By employing tools such as the “5 Whys” and fishbone diagrams, they systematically traced the failures back to specific actions and oversight lapses. This thorough investigation revealed that many team members were unaware of the latest safety protocols, highlighting a critical gap in training and communication.

5 Whys Analysis (Drill-Down to Root Cause)

Problem: Workers failed to follow safety protocols, leading to incidents.

| Why? | Answer | Actionable Insight |

|---|---|---|

| 1st Why: Why safety violations? | Workers ignored protocols. | Protocols were unclear. |

| 2nd Why: Why unclear protocols? | No recent training updates. | Training was outdated. |

| 3rd Why: Why outdated training? | No budget allocated. | Safety wasn’t prioritized. |

| 4th Why: Why no priority? | Leadership focused on deadlines. | Culture of “speed over safety.” |

| 5th Why: Why this culture? | No penalties for safety lapses. | Root Cause: Lack of accountability. |

Based on these findings, the management implemented targeted training programs aimed at addressing the identified deficiencies. Regular safety audits were instituted, and a new communication strategy was developed to ensure that all team members were aligned with safety procedures and expectations. As a result, the effectiveness of safety inspections increased significantly, and incidents declined within six months.

Ultimately, the application of RCA led to a transformative change in the project’s execution. The Silver Oak High-Rise Project not only overcame its initial setbacks but also completed on schedule with enhanced safety practices and improved team cohesion. This case underscores the value of employing Root Cause Analysis in the construction industry, as it can lead to substantial improvements in operational efficiency and safety outcomes.

Challenges in Implementing Root Cause Analysis

Implementing Root Cause Analysis (RCA) within the construction industry poses several significant challenges that can hinder its effectiveness. One of the primary obstacles is resistance to change among staff and management. Many employees may be accustomed to existing workflows, making the transition to a systematic approach like RCA difficult. This reluctance can stem from a fear of the unknown, where individuals may doubt the efficacy of the new process or feel threatened by the scrutiny that follows the identification of problems. To address this, it is crucial to foster a culture that encourages open communication and emphasizes the benefits of RCA, thereby easing apprehensions and facilitating acceptance.

A further challenge is the lack of training available for personnel regarding RCA methodologies. Many construction workers, project managers, and supervisors may not have received the necessary education or training to effectively conduct a thorough analysis of problems. Without proper guidance, the RCA process can appear convoluted or intimidating, potentially leading to incomplete analyses that fail to identify underlying issues. To mitigate this challenge, organizations should invest in comprehensive training programs that encompass essential RCA techniques and provide continuous learning opportunities for staff at all levels.

Lastly, inadequate data can severely impede the RCA process. Construction projects often generate vast amounts of data, but not all of it is relevant or accurately recorded. Incomplete or poor-quality data can obscure the root causes of issues, complicating efforts to address them. To overcome this hurdle, companies should establish robust data collection and management systems, ensuring accurate, relevant, and timely information is available for analysis. By promoting a proactive approach to collecting and utilizing data, organizations can significantly enhance their RCA processes and ultimately improve project outcomes and safety standards in the construction sector.

Conclusion: The Path Forward in Construction Industry RCA

Root Cause Analysis (RCA) serves as a fundamental methodology within the construction industry, significantly influencing the safety and efficiency of construction projects. As highlighted throughout this discussion, the application of RCA enables stakeholders to identify the underlying reasons for issues that may arise during project execution. By systematically investigating failures and problems, construction managers can implement solutions that not only resolve immediate concerns but also prevent recurrence in the future.

The importance of RCA cannot be overstated. It fosters a proactive culture that prioritizes safety and efficiency over reactionary measures. When teams engage in comprehensive analyses of accidents, delays, and resource inefficiencies, they cultivate a deeper understanding of the operational landscape. This knowledge ultimately translates into enhanced project performance, reduced costs, and improved safety outcomes. As more construction firms adopt RCA techniques, we may observe a notable shift towards a more methodical approach to problem-solving in the industry.

Looking ahead, the construction industry stands at a pivotal juncture where the incorporation of Root Cause Analysis into standard practice is not merely advantageous—it is essential. The benefits of embracing RCA practices extend beyond immediate project gains; they encompass long-term impacts on industry reputation, regulatory compliance, and overall workforce morale. By investing in training and resources that support RCA application, organizations are positioning themselves to meet the evolving demands of the industry while enhancing their competitive edge.

Encouraging a culture of continuous learning and improvement through RCA can inspire both established companies and newcomers to innovate and refine their processes. The future of the construction industry is contingent upon the willingness to adapt and commit to thorough analysis and resolution of problems. Ultimately, by prioritizing Root Cause Analysis, the construction sector can aspire to not only meet today’s challenges but also pave the way for a safer, more efficient future.