Introduction

Building a home in India is one of the most significant investments most people make in their lifetime. However, the construction industry is riddled with pitfalls that can turn your dream home into a financial nightmare. From planning oversights to execution errors, construction mistakes can cost homeowners lakhs of rupees and years of frustration.

This comprehensive guide addresses the most critical mistakes that plague house construction projects across India. Whether you’re a first-time home builder, a real estate developer, or a construction professional, understanding these common pitfalls will help you make informed decisions and avoid costly errors.

Who Should Read This Guide:

- Individuals planning to build their first home

- Real estate developers and investors

- Construction professionals and contractors

- Architecture and engineering students

- Property consultants and advisors

The insights shared here are based on industry best practices, Indian Standard (IS) codes, and real-world construction experiences across different climatic zones of India.

Key Methodologies & Processes

Step-by-Step Construction Planning Framework

Pre-Construction Planning (Months 1-3)

- Site survey and soil testing (IS 2720 standards)

- Architectural design and structural planning

- Regulatory approvals and NOCs

- Material procurement and contractor selection

- Timeline and budget finalization

Foundation and Structure (Months 4-8)

- Excavation and foundation laying

- Plinth beam and column construction

- Slab casting and curing (IS 456 compliance)

- Load-bearing wall construction

- Quality checks at each stage

Finishing and Handover (Months 9-12)

- Electrical and plumbing installations

- Flooring and wall finishing

- Waterproofing and painting

- Final inspections and certifications

- Handover documentation

Relevant IS Codes and Standards

- IS 456:2000 – Plain and Reinforced Concrete Code of Practice

- IS 1893:2016 – Criteria for Earthquake Resistant Design

- IS 3362:1977 – Natural Ventilation Code

- IS 1742:1983 – Building Drainage Code

- IS 2720 – Methods of Test for Soils

- NBC 2016 – National Building Code of India

Material & Manpower Requirements

Essential Materials for Quality Construction

Structural Materials:

- Portland Pozzolana Cement (PPC) or Ordinary Portland Cement (OPC)

- TMT steel bars (Fe 415 or Fe 500 grade)

- Aggregates (20mm and 10mm stone chips)

- Sand (river sand preferred over M-sand)

- Bricks (clay bricks or AAC blocks)

Finishing Materials:

- Vitrified tiles or ceramic tiles for flooring

- Paints (acrylic emulsion for interiors, weather-resistant for exteriors)

- Electrical cables and conduits (ISI marked)

- Plumbing pipes (CPVC or PPR pipes)

- Waterproofing compounds and membranes

Labor and Machinery Requirements

Skilled Labor:

- Civil engineers and site supervisors

- Masons and bar benders

- Electricians and plumbers

- Painters and tile fixers

Machinery and Equipment:

- Concrete mixer or ready-mix concrete

- Water tankers for curing

- Scaffolding and safety equipment

- Vibrators for concrete compaction

Top 10 Critical Construction Mistakes to Avoid

1. Starting Construction Without Approved Plans

The Mistake: Many homeowners begin construction with basic sketches or unapproved plans to save time and money.

The Impact: Municipal authorities can issue stop-work notices, demand demolition, or impose penalty fees up to 100% of the property value. In cities like Bangalore and Mumbai, thousands of unauthorized constructions face legal action annually.

The Solution: Always obtain building plan approval from local authorities before starting construction. Submit detailed architectural drawings, structural designs, and obtain necessary NOCs from fire, environment, and other departments.

2. Ignoring Soil Testing and Foundation Design

The Mistake: Skipping soil investigation and using standard foundation designs without considering soil conditions.

The Impact: Black cotton soil, common in Maharashtra and Madhya Pradesh, can cause foundation settlement and structural cracks. Poor soil bearing capacity can lead to uneven settling, costing ₹2-5 lakhs in remedial work.

The Solution: Conduct soil testing as per IS 2720 standards. For black cotton soil, use deep foundations or soil stabilization techniques. Design foundations based on actual soil bearing capacity, not assumptions.

3. Compromising on Material Quality to Cut Costs

The Mistake: Purchasing substandard cement, steel, or other materials from unauthorized dealers to save 10-15% on costs.

The Impact: Fake ISI-marked steel can fail load tests, leading to structural failures. Poor-quality cement reduces concrete strength by 20-30%, compromising building safety.

The Solution: Buy materials only from authorized dealers. Verify ISI/BIS marks and test certificates. Remember that saving ₹50,000 on materials can cost ₹5 lakhs in repairs later.

4. Poor Ventilation and Natural Light Planning

The Mistake: Designing rooms without adequate ventilation or natural light to maximize floor space.

The Impact: Inadequate ventilation violates IS 3362 standards and creates health issues. Poor natural light increases electricity costs by ₹3,000-5,000 annually.

The Solution: Ensure minimum 10% of floor area as window opening for natural ventilation. Plan for cross-ventilation in all habitable rooms. Use light wells or skylights for interior spaces.

5. Incorrect Waterproofing Implementation

The Mistake: Using cheap waterproofing materials or poor application techniques, especially on terraces and bathrooms.

The Impact: Terrace leakage repairs cost ₹500-800 per square foot post-construction. Water seepage can damage electrical systems and create structural problems.

The Solution: Use quality waterproofing membranes and ensure proper slope (1:100) for drainage. Apply waterproofing in layers and conduct water testing before final finishing.

6. Inadequate Electrical Planning and Conduit Layout

The Mistake: Insufficient electrical points and poor conduit planning for future needs.

The Impact: Chasing walls for additional wiring costs ₹200-300 per point. Surface conduits spoil aesthetics and are prone to damage.

The Solution: Plan for modern electrical needs including inverter points, AC outlets, and smart home provisions. Use concealed conduits and provide 20% extra capacity for future additions.

7. Hiring Unregistered or Inexperienced Contractors

The Mistake: Selecting contractors based solely on lowest quotes without checking credentials or past work.

The Impact: Poor workmanship leads to defects, delays, and no warranty coverage. Rework can cost 15-20% of the total project value.

The Solution: Hire registered contractors with valid licenses. Check their previous projects and client references. Include workmanship warranty clauses in contracts.

8. Ignoring Climate-Specific Design Requirements

The Mistake: Using generic designs without considering local climate conditions.

The Impact: Glass facades in hot climates increase cooling costs by 30-40%. Flat roofs in heavy rainfall areas cause leakage problems.

The Solution: Design for local climate conditions. Use appropriate materials, colors, and architectural features. Consult local architects familiar with regional requirements.

9. No Provision for Future Expansion

The Mistake: Not planning for vertical or horizontal expansion possibilities.

The Impact: Load-bearing walls prevent future expansion. Adding floors later requires expensive structural modifications.

The Solution: Design with expansion possibilities in mind. Provide for staircase extensions and ensure structural capacity for additional floors. Avoid load-bearing walls where expansion is planned.

10. Inadequate Financial Planning and Contingency Budgets

The Mistake: Underestimating project costs and not maintaining contingency funds.

The Impact: Cost overruns of 20-30% are common in construction projects. Lack of funds can halt construction mid-way, leading to material wastage and contractor disputes.

The Solution: Prepare detailed cost estimates with 15-20% contingency buffer. Track expenses regularly and maintain cash flow projections. Consider material price fluctuations in planning.

Deliverables at Each Stage

Pre-Construction Stage

- Site Survey Report: Detailed topographical and soil investigation

- Approved Building Plans: Municipal approval and NOCs

- Structural Design: Engineer-approved structural drawings

- Cost Estimates: Detailed material and labor cost breakdown

- Timeline: Project schedule with milestones

Construction Stage

- Foundation Certificate: Structural engineer’s foundation approval

- Concrete Test Reports: Cube strength test reports (₹2,000 per test)

- Progress Reports: Weekly/monthly construction progress updates

- Quality Checklists: Stage-wise quality compliance verification

- Safety Compliance: Safety audit reports and certifications

Post-Construction Stage

- Completion Certificate: Municipal completion and occupancy certificate

- Structural Stability Certificate: Engineer’s structural stability report

- Warranty Documents: Material and workmanship warranty papers

- Maintenance Manual: Building maintenance guidelines and schedules

- As-Built Drawings: Final construction drawings with modifications

Stakeholders & Communication Matrix

Key Stakeholders

Primary Stakeholders:

- Property Owner/Client

- Architect and Structural Engineer

- Main Contractor and Subcontractors

- Municipal Authorities and Regulators

Secondary Stakeholders:

- Material Suppliers and Vendors

- Labor Supervisors and Skilled Workers

- Neighbors and Community Members

- Banks and Financial Institutions (if loan involved)

Communication Protocols

Daily Communications:

- Site progress reports between contractor and owner

- Material delivery and quality verification

- Safety compliance and worker coordination

Weekly Communications:

- Progress review meetings with all stakeholders

- Cost tracking and budget variance analysis

- Quality inspection reports and corrective actions

Monthly Communications:

- Formal progress presentations with photos/videos

- Financial reconciliation and payment processing

- Regulatory compliance and inspection coordination

Value Engineering Opportunities

Cost-Saving Techniques Without Quality Compromise

Material Optimization:

- Use AAC blocks instead of clay bricks (20% weight reduction, better insulation)

- Replace marble with vitrified tiles (50% cost saving with similar aesthetics)

- Use PPR pipes instead of copper (60% cost reduction with equal durability)

Design Optimization:

- Optimize column and beam sizes through structural analysis

- Use precast elements for repetitive components

- Implement modular design concepts for cost efficiency

Construction Process Improvements:

- Use ready-mix concrete instead of on-site mixing (better quality, time saving)

- Implement lean construction principles to reduce waste

- Coordinate trades to minimize rework and delays

Sustainable Alternatives

Energy-Efficient Solutions:

- LED lighting systems (70% energy saving)

- Solar water heating systems (60% energy cost reduction)

- Insulated roofing and wall systems (30% cooling cost reduction)

Water Conservation:

- Rainwater harvesting systems (mandatory in many cities)

- Greywater recycling for gardening

- Low-flow fixtures and dual-flush toilets

Eco-Friendly Materials:

- Fly ash bricks (utilizes industrial waste)

- Recycled steel and aggregates

- Bamboo and other renewable materials for non-structural elements

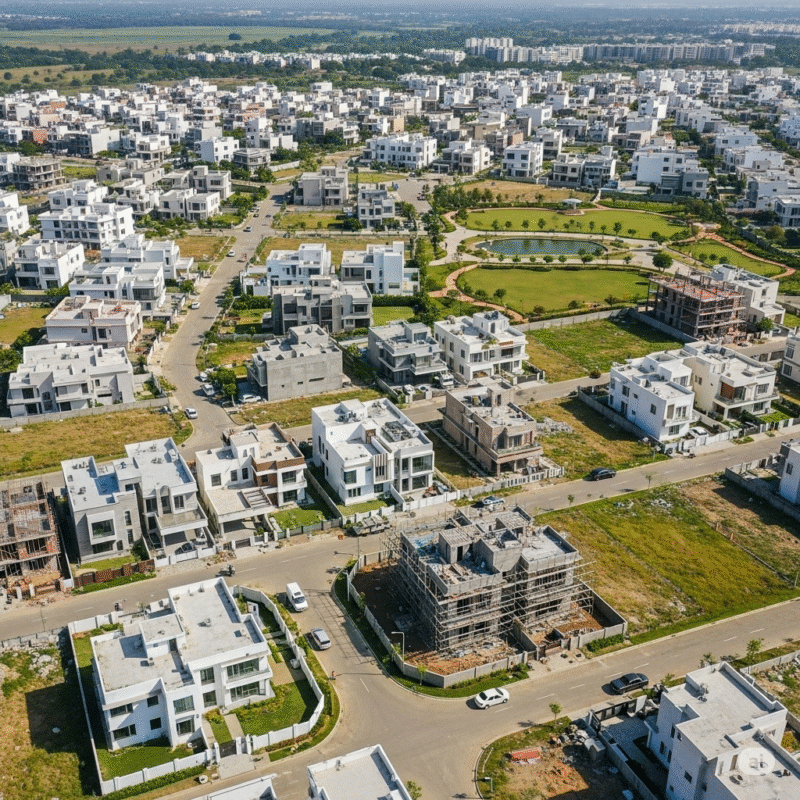

Case Study: Residential Villa Construction in Gurgaon

Project Overview

Location: Sector 57, Gurgaon, Haryana

Type: 4-bedroom villa with basement

Built-up Area: 4,500 sq ft

Budget: ₹1.2 crores

Timeline: 18 months (planned), 24 months (actual)

Challenges Faced and Solutions Implemented

Soil Issues

- Problem: High water table and soft clay soil discovered during excavation

- Solution: Implemented dewatering system and used pile foundation instead of isolated footings

- Cost Impact: Additional ₹8 lakhs, but prevented future settlement issues

Regulatory Delays

- Problem: Building plan approval delayed by 4 months due to setback violations

- Solution: Redesigned to comply with setback requirements and expedited approval process

- Time Impact: 6-month delay, but avoided legal complications

Material Price Escalation

- Problem: Steel prices increased by 25% during construction period

- Solution: Negotiated with suppliers for bulk purchase and fixed-rate contracts

- Cost Management: Limited cost overrun to 8% instead of projected 15%

Results and Key Takeaways

Positive Outcomes:

- Structural stability with no foundation settlement after 3 years

- Energy-efficient design reduced operating costs by 40%

- Quality construction with minimal defects during warranty period

Lessons Learned:

- Soil testing is crucial and should never be skipped

- Regulatory compliance saves time and money in the long run

- Material procurement strategy significantly impacts project costs

- Regular supervision and quality checks prevent major defects

Financial Summary:

- Original Budget: ₹1.2 crores

- Final Cost: ₹1.38 crores (15% overrun within acceptable range)

- Current Market Value: ₹2.1 crores (52% appreciation in 3 years)

Risks & Mitigation Strategies

Common Construction Risks

1. Cost Overrun Risks

- Risk Factors: Material price fluctuation, scope changes, poor planning

- Mitigation: Detailed cost estimation, contingency planning, regular budget monitoring

- Tools: Cost tracking software, material price index monitoring

2. Time Delay Risks

- Risk Factors: Weather conditions, material shortage, labor issues

- Mitigation: Realistic scheduling, alternative material sources, skilled labor contracts

- Tools: Critical path method (CPM), weather-adjusted schedules

3. Quality and Safety Risks

- Risk Factors: Poor workmanship, substandard materials, inadequate supervision

- Mitigation: Quality control protocols, material testing, safety training

- Tools: Quality checklists, third-party inspections, safety audits

4. Legal and Regulatory Risks

- Risk Factors: Non-compliance with building codes, environmental regulations

- Mitigation: Legal compliance review, regular inspections, documentation

- Tools: Compliance checklists, legal consultation, regular audits

Risk Assessment Tools

Risk Matrix Framework:

- Probability assessment (High/Medium/Low)

- Impact evaluation (Critical/Major/Minor)

- Risk scoring and prioritization

- Mitigation strategy development

Preventive Measures:

- Pre-construction risk assessment workshops

- Regular risk review meetings during construction

- Documentation of risk mitigation actions

- Continuous monitoring and adjustment of risk strategies

Material Cost Comparison Table

| Material Category | Premium Option | Standard Option | Budget Option | Cost Difference |

|---|---|---|---|---|

| Flooring | Imported Marble | Vitrified Tiles | Ceramic Tiles | 300% vs 100% vs 60% |

| Paint | Premium Acrylic | Standard Emulsion | Basic Distemper | 200% vs 100% vs 40% |

| Electrical | Branded Switches | Standard Switches | Local Switches | 250% vs 100% vs 50% |

| Plumbing | Copper Pipes | PPR Pipes | PVC Pipes | 400% vs 100% vs 60% |

Conclusion & Further Reading

Building a house in India requires careful planning, quality execution, and continuous monitoring. The ten critical mistakes outlined in this guide represent the most common and costly errors that can derail your construction project. By understanding these pitfalls and implementing the suggested solutions, you can save significant time, money, and frustration.

Key Takeaways:

- Never compromise on planning and regulatory approvals

- Invest in quality materials and skilled labor

- Implement proper supervision and quality control measures

- Plan for contingencies and future needs

- Focus on climate-appropriate and sustainable design solutions

Success Factors for Construction Projects:

- Detailed planning and realistic budgeting

- Compliance with building codes and regulations

- Regular quality inspections and third-party audits

- Proper documentation and communication protocols

- Long-term thinking for maintenance and sustainability

Internal Links (Suggested)

- [Complete Guide to Building Plan Approval Process in India]

- [Soil Testing for Construction: A Comprehensive Guide]

- [Material Quality Testing and Certification in India]

- [Contractor Selection Criteria for Home Construction]

- [Waterproofing Solutions for Indian Climate Conditions]

External Resources

- Bureau of Indian Standards (BIS): Official IS Codes and Standards

- National Building Code of India 2016: Complete building regulations

- Central Public Works Department (CPWD): Construction guidelines and rates

- Indian Concrete Institute: Technical resources for concrete construction

- Energy Efficiency Services Limited (EESL): Energy-efficient building solutions

Remember, successful construction is not about cutting costs but about optimizing value. Invest in quality planning, materials, and execution to create a home that serves you well for decades to come.