Introduction

A Quality Assurance Plan (QAP) is the backbone of successful construction projects, ensuring that every phase meets predetermined quality standards while complying with regulatory requirements. In today’s competitive construction industry, having a robust QAP is not just beneficial—it’s mandatory under regulations like RERA, ISO 9001, and the National Building Code (NBC) 2016.

Quality assurance goes beyond simple quality control. While quality control focuses on detecting defects in finished products, quality assurance is a proactive process that prevents defects from occurring in the first place. This systematic approach ensures that construction projects deliver value to stakeholders while minimizing rework, delays, and cost overruns.

Key Methodologies & Processes

Foundations of Quality Assurance Plan

Understanding QA vs QC Quality Assurance (QA) is process-focused, emphasizing prevention through systematic activities. Quality Control (QC) is product-focused, involving inspection and testing to identify defects. A comprehensive QAP integrates both approaches for maximum effectiveness.

Regulatory Compliance Framework

- RERA (Real Estate Regulatory Authority): Mandates quality standards for residential projects

- ISO 9001: International quality management system standards

- NBC 2016: National Building Code requirements for structural safety and quality

Step-by-Step Quality Assurance Plan Development

Project Assessment and Scope Definition Begin by conducting a thorough project analysis, identifying critical quality parameters, and defining the scope of quality assurance activities. This includes understanding project complexity, environmental factors, and stakeholder expectations.

Risk Assessment and Identification Identify potential quality risks across three critical areas:

- Material risks (substandard supplies, storage issues)

- Design risks (clash detection, specification errors)

- Labor risks (skill gaps, training needs)

Quality Objectives and KPIs Establish measurable quality objectives such as:

- Rework rate ≤2%

- 100% compliance with material testing requirements

- Zero safety incidents

- On-time delivery within quality parameters

Inspection and Test Plans (ITP) Develop detailed ITPs specifying:

- Inspection frequencies (e.g., slump tests every 50m³ concrete pour)

- Hold points requiring approval before proceeding

- Witness points for critical activities

- Testing schedules aligned with IS codes

Material & Manpower Requirements

Material Procurement Standards

Approved Vendor Management Maintain approved vendor lists with IS code compliance verification. Key materials require specific certifications:

- Concrete: IS 456 compliance for mix design and strength

- Steel reinforcement: IS 1786 for TMT bars

- Cement: IS 8112 for ordinary Portland cement

- Aggregates: IS 383 for coarse and fine aggregates

Material Testing Requirements Implement systematic testing protocols:

- Concrete cubes testing per IS 516

- Soil compaction testing per IS 2720

- Steel tensile strength testing per IS 1608

Manpower and Competency Requirements

Skilled Labor Certification Ensure workers possess appropriate certifications:

- Welding: IS 7307 certified welders

- Masonry: IS 2212 compliant masons

- Electrical work: Licensed electricians per IE rules

Training Programs Implement continuous training through:

- Daily 10-minute toolbox talks

- Monthly technical skill development sessions

- Safety awareness programs

- Quality consciousness workshops

Deliverables at Each Stage

Pre-Construction Phase

Risk Assessment Report Document identifying potential quality risks with mitigation strategies. This report should include:

- Material supply chain analysis

- Environmental impact assessment

- Regulatory compliance checklist

- Resource availability verification

Design Review Documentation Comprehensive design validation using:

- BIM clash detection reports (Navisworks/Revit)

- Structural analysis verification

- MEP coordination drawings

- Value engineering recommendations

Material Procurement Plan Detailed procurement strategy including:

- Approved vendor lists with quality certifications

- Material testing schedules

- Storage and handling procedures

- Quality acceptance criteria

Construction Phase

Daily Quality Checklists Implement activity-specific checklists:

Formwork Checklist (IS 14687 compliance):

- Alignment verification within tolerance limits

- Shoring adequacy and stability

- Surface finish and cleanliness

- Removal timing and procedures

Reinforcement Checklist (IS 2502 compliance):

- Bar diameter and grade verification

- Lap length calculations and implementation

- Cover block placement and adequacy

- Binding wire quality and spacing

Concrete Pouring Checklist:

- Mix design approval and verification

- Slump test results documentation

- Placement methodology compliance

- Curing procedure implementation

Non-Conformance Reports (NCR) Systematic documentation of quality deviations including:

- Detailed defect description

- Root cause analysis

- Corrective action plans

- Preventive measures implementation

- Verification of corrections

Post-Construction Phase

Snagging Lists Comprehensive defect identification using digital tools like Fieldwire:

- Visual inspection reports

- Functional testing results

- Finishing quality assessment

- MEP system verification

Handover Documentation Complete documentation package including:

- As-built drawings

- Material test certificates

- Warranty documents

- Operation and maintenance manuals

- Statutory approvals and clearances

Stakeholders & Communication Matrix

Key Stakeholders and Responsibilities

Project Owner/Client

- Define quality expectations and standards

- Approve QAP and major quality decisions

- Provide necessary resources for quality implementation

- Review and accept quality deliverables

Main Contractor

- Implement QAP across all project activities

- Coordinate subcontractor quality activities

- Maintain quality documentation

- Conduct internal quality audits

Subcontractors

- Comply with specified quality requirements

- Provide skilled labor and quality materials

- Participate in quality training programs

- Report quality issues promptly

Third-Party Quality Auditors

- Conduct independent quality assessments

- Verify compliance with standards and specifications

- Provide objective quality reports

- Recommend improvement measures

Government Authorities

- Review and approve statutory requirements

- Conduct regulatory inspections

- Issue necessary clearances and permits

- Ensure compliance with building codes

Communication Protocols

Weekly Quality Meetings Structured meetings addressing:

- Quality performance review

- Non-conformance status updates

- Upcoming critical activities

- Resource requirements and issues

Monthly Quality Reports Comprehensive reports including:

- Quality metrics and KPI performance

- Trend analysis and improvement areas

- Compliance status with regulations

- Training and competency updates

Real-Time Communication Systems Digital platforms enabling:

- Instant quality issue reporting

- Document sharing and version control

- Mobile inspection and testing apps

- Automated compliance tracking

Value Engineering Opportunities

Cost-Saving Techniques

Alternative Material Selection

- Fly ash concrete for reduced cement consumption

- Precast elements for faster construction and better quality

- Recycled aggregates where specifications permit

- Energy-efficient building materials for long-term savings

Construction Method Optimization

- Modular construction techniques

- Advanced formwork systems for faster turnover

- Mechanized construction for improved quality

- Prefabrication to reduce on-site quality risks

Sustainable Alternatives

Green Building Materials

- Recycled steel reinforcement

- Low-carbon concrete mixes

- Sustainable timber from certified sources

- Energy-efficient insulation materials

Water and Energy Conservation

- Rainwater harvesting systems

- Solar water heating integration

- LED lighting systems

- Smart building automation systems

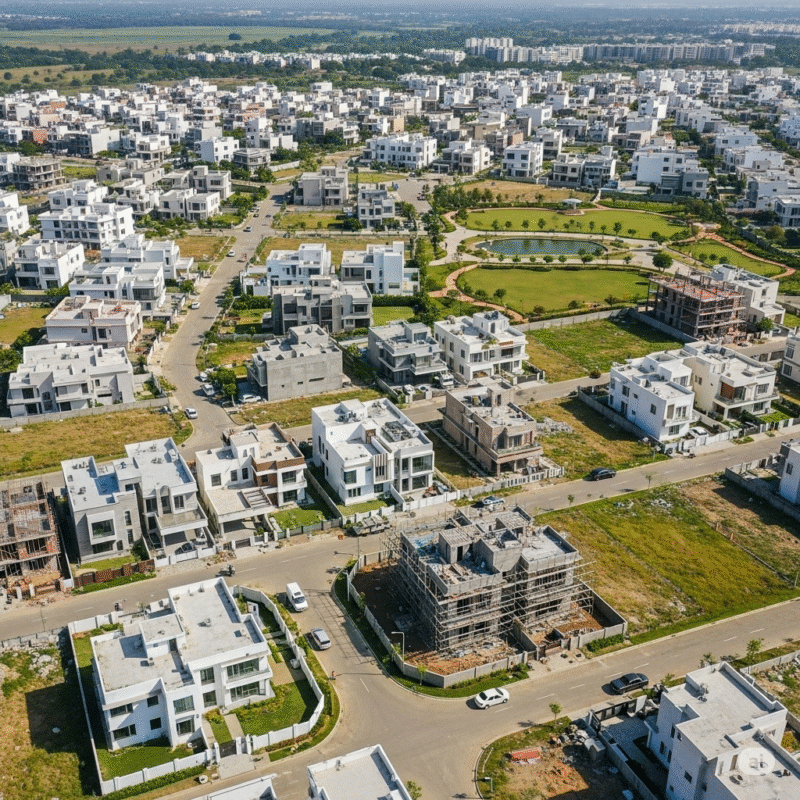

Case Study: Residential Complex Quality Assurance Plan Implementation

Project Overview

A 500-unit residential complex in Bangalore implemented a comprehensive QAP resulting in significant quality improvements and cost savings.

Project Details:

- Built-up area: 2.5 million sq ft

- Project duration: 36 months

- Total project cost: ₹800 crores

- Quality investment: 2.5% of project cost

Challenges Faced

Material Quality Issues Initial challenges with inconsistent concrete strength led to implementation of:

- Enhanced supplier qualification process

- On-site concrete batching plant

- Real-time strength monitoring systems

- Dedicated quality control laboratory

Coordination Problems Multiple trade coordination issues resolved through:

- BIM-based clash detection

- Weekly coordination meetings

- Digital communication platforms

- Integrated project scheduling

Solutions Implemented

Digital Quality Management

- Procore platform for real-time quality tracking

- Mobile inspection apps for field teams

- Automated compliance reporting

- Digital document management system

Enhanced Testing Protocols

- NABL-certified laboratory partnership

- Increased testing frequency for critical materials

- Third-party validation for structural elements

- Regular calibration of testing equipment

Results and Key Takeaways

Quantifiable Improvements:

- Rework reduced from 8% to 1.5%

- Defect density decreased by 75%

- Customer satisfaction increased to 92%

- Project completed 2 months ahead of schedule

Key Success Factors:

- Strong management commitment to quality

- Comprehensive training programs

- Technology-enabled quality monitoring

- Collaborative stakeholder approach

Risks & Mitigation Strategies

Common Quality Risks

Material-Related Risks

- Substandard material supply

- Inadequate storage and handling

- Counterfeit materials in supply chain

- Quality deterioration during transportation

Process-Related Risks

- Inadequate quality control procedures

- Insufficient testing and inspection

- Poor workmanship and skill gaps

- Inadequate supervision and monitoring

Environmental Risks

- Weather impact on construction quality

- Soil conditions affecting foundation quality

- Site accessibility limiting quality control

- Environmental compliance challenges

Preventive Measures

Material Quality Assurance

- Establish approved vendor networks

- Implement incoming material inspection

- Use NABL-certified testing laboratories

- Maintain proper storage facilities

Process Quality Control

- Develop detailed work procedures

- Implement checkpoint inspection systems

- Provide regular skills training

- Use digital monitoring tools

Risk Assessment Tools

- Failure Mode and Effects Analysis (FMEA)

- Quality risk registers and matrices

- Regular risk review meetings

- Contingency planning for critical risks

Technology Integration in Quality Assurance Plan

Digital QA Platforms

Comprehensive Project Management Tools Modern Quality Assurance Plan implementation leverages platforms like:

- Procore: Real-time quality tracking and reporting

- Autodesk BIM 360: Integrated design and quality management

- PlanGrid: Digital blueprint and inspection management

- Fieldwire: Mobile-first quality and task management

Advanced Monitoring Technologies

Drones and IoT Integration

- Progress monitoring through aerial surveys

- Thermal imaging for concrete curing verification

- Structural health monitoring sensors

- Real-time environmental condition tracking

AI-Powered Quality Control

- OpenCV-based crack detection systems

- Machine learning for defect pattern recognition

- Automated compliance checking

- Predictive quality analytics

Training and Competency Development

Structured Training Programs

Technical Skills Development

- Material testing and quality control procedures

- Reading and interpreting technical drawings

- Understanding IS codes and specifications

- Using digital quality management tools

Quality Awareness Programs

- Quality culture development workshops

- Cost of quality understanding sessions

- Customer satisfaction importance training

- Continuous improvement methodologies

Certification and Competency Management

Professional Certifications

- Project Management Professional (PMP) for managers

- Certified Quality Engineer (CQE) for quality personnel

- NEBOSH certification for safety integration

- Green building certification programs

Continuous Improvement Framework

Lessons Learned Repository

Knowledge Management System Maintain a comprehensive database of:

- Past project quality issues and solutions

- Best practices and innovative techniques

- Supplier performance evaluations

- Technology implementation experiences

Benchmarking and Performance Analysis

Industry Benchmarking Regular comparison with industry leaders like L&T, DLF, and international standards:

- Quality performance metrics comparison

- Best practice identification and adoption

- Innovation and technology benchmarking

- Customer satisfaction measurement

Internal Performance Tracking

- Monthly quality dashboards

- Trend analysis and predictive indicators

- Root cause analysis for recurring issues

- Improvement opportunity identification

Quality Assurance Templates and Checklists

Residential Project QAP Focus Areas

Finishing Quality Checklists

- Wall plastering and painting standards

- Flooring installation and finishing

- Door and window installation quality

- Electrical and plumbing fixture installation

MEP System Quality Verification

- Electrical safety and compliance testing

- Plumbing pressure testing and leak detection

- HVAC system commissioning and performance

- Fire safety system testing and certification

Infrastructure Project QAP (Highway Example)

Material Testing Requirements

- Bitumen quality testing per MORTH specifications

- Aggregate gradation and quality verification

- Soil compaction testing and certification

- Concrete strength testing for structures

Construction Quality Control

- Road alignment and camber verification

- Layer thickness and compaction monitoring

- Drainage system functionality testing

- Safety infrastructure installation quality

Post-Construction Quality Management

Snagging and Defect Management

Digital Snagging Process Using tools like Fieldwire for:

- Photographic documentation of defects

- Priority-based defect categorization

- Responsibility assignment and tracking

- Completion verification and sign-off

Quality Handover Process

- Final inspection and quality certification

- Documentation handover with quality records

- Warranty registration and explanation

- Customer training on maintenance procedures

Warranty and Defect Liability Management

5-Year Defect Tracking System

- Digital warranty management platform

- Proactive maintenance scheduling

- Customer feedback and satisfaction monitoring

- Defect trend analysis for future improvements

Conclusion & Further Reading

Implementing a comprehensive Quality Assurance Plan is essential for successful construction projects in today’s regulatory environment. The systematic approach outlined in this guide provides a framework for achieving consistent quality while managing costs and timelines effectively.

Key takeaways for successful QAP implementation:

- Early planning and stakeholder engagement are crucial

- Technology integration enhances quality monitoring capabilities

- Continuous training and competency development ensure sustained quality

- Regular auditing and improvement drive long-term success

The construction industry continues to evolve with new technologies, materials, and methodologies. Staying updated with latest trends, regulations, and best practices is essential for maintaining competitive advantage and delivering superior quality projects.

External References:

- Bureau of Indian Standards (BIS) codes and specifications

- National Building Code of India 2016

- RERA guidelines for real estate projects

- ISO 9001:2015 quality management system requirements

Professional Development:

- Indian Concrete Institute (ICI) training programs

- Construction Industry Development Council (CIDC) certifications

- Project Management Institute (PMI) construction specialization

- Green building certification courses (IGBC, LEED)