Introduction

Construction contracts form the backbone of every building project, from small residential homes to massive infrastructure developments. Whether you’re a fresh graduate entering the construction industry, an experienced developer planning your next project, or a homeowner embarking on your dream house construction, understanding different contract types is crucial for project success.

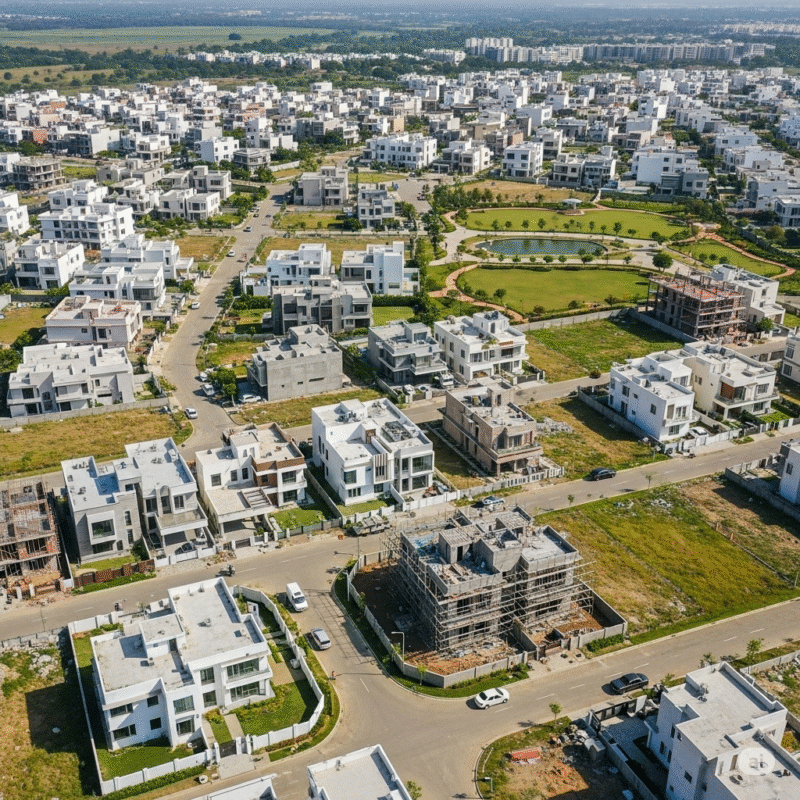

In India’s rapidly growing construction sector, choosing the right contract type can mean the difference between a profitable project and a financial disaster. With the real estate market valued at over ₹13 trillion and growing at 7% annually, proper contract management has become more critical than ever.

Who Should Read This Guide?

- Construction and real estate professionals (freshers and experienced)

- Real estate developers and investors

- Individuals planning to build their homes

- Students working on construction project reports

- Consultants and project managers

This comprehensive guide will walk you through the three primary contract types used in Indian construction: Lump Sum, Item Rate, and EPC contracts, helping you make informed decisions for your projects.

Construction Contract Types and Their Methodologies

1. Lump Sum Contracts (Fixed Price Contracts)

Definition and Execution Process: Lump sum contracts involve a fixed price for the entire project scope, regardless of actual costs incurred by the contractor. The execution follows these steps:

- Tender Preparation: Detailed drawings and specifications are prepared

- Cost Estimation: Contractors estimate total project cost including materials, labor, and profit

- Bid Submission: Fixed price quotes are submitted

- Contract Award: Lowest technically qualified bidder wins

- Execution: Work proceeds as per agreed scope and timeline

IS Codes and Standards:

- IS 1200 (Part 1-27): Method of Measurement of Building and Civil Engineering Works

- CPWD Works Manual for government projects

Best Industry Practices:

- Conduct thorough site surveys before quoting

- Include 5-10% contingency for unforeseen circumstances

- Clearly define scope boundaries and exclusions

- Regular progress monitoring and quality checks

2. Item Rate Contracts (Unit Price Contracts)

Definition and Execution Process: Item rate contracts involve predetermined rates for individual work items, with final payment based on actual quantities executed:

- BOQ Preparation: Detailed Bill of Quantities with estimated quantities

- Rate Fixation: Unit rates for each item are determined through tendering

- Measurement: Actual work quantities are measured during execution

- Payment: Unit rate × Actual quantity for each item

Execution Standards:

- Follow IS 1200 for measurement procedures

- Maintain detailed measurement books

- Regular joint measurements by client and contractor

- Quarterly rate revisions for long-duration projects

3. EPC Contracts (Engineering, Procurement, Construction)

Definition and Execution Process: EPC contracts provide single-point responsibility for design, procurement, and construction:

- Conceptual Design: Based on client’s functional requirements

- Detailed Engineering: Complete design development

- Procurement: Material sourcing and vendor management

- Construction: Site execution and commissioning

- Handover: Complete project delivery with warranties

International Standards:

- FIDIC Silver Book conditions for EPC contracts

- ISO 9001 for quality management

- ISO 14001 for environmental management

- OHSAS 18001 for safety management

| Contract Type | Key Characteristics | Pros | Cons |

| Lump Sum 💰 | * Fixed total cost agreed upfront. * Contractor bears cost overrun risks. * Best for well-defined projects (e.g., residential buildings). | Budget certainty, simple administration | Less flexibility for changes |

| Item Rate 📊 | * Payment based on measured quantities (e.g., per unit of material). * Client pays for actual work done. * Common in infrastructure (roads, utilities). | Fair pricing, adaptable to scope changes | Final cost uncertain, more paperwork |

| EPC 🏗️ | * Contractor handles Engineering, Procurement, Construction. * Turnkey solution (client gets ready-to-use project). * Used in large-scale projects (power plants, factories). | Single-point responsibility, faster completion | Higher initial cost, complex negotiations |

Material and Manpower Requirements

Typical Materials by Contract Type

Lump Sum Projects:

- Pre-quantified materials based on detailed estimates

- Bulk procurement for cost optimization

- Standard specifications (Grade M25 concrete, Fe500 steel)

Item Rate Projects:

- Materials procured as per actual consumption

- Flexible specifications allowing alternatives

- Regular material reconciliation required

EPC Projects:

- High-quality materials meeting international standards

- Comprehensive material testing and certification

- Supply chain management across multiple vendors

Labor and Machinery Requirements

Skilled Manpower:

- Project managers and site engineers

- Quality control inspectors

- Safety officers and supervisors

- Specialized technicians for MEP works

Machinery Requirements:

- Earth moving equipment (excavators, dozers)

- Concrete equipment (batching plants, pumps)

- Lifting equipment (cranes, hoists)

- Finishing equipment (grinders, polishers)

Manpower Planning Matrix:

| Contract Type | Project Manager | Site Engineers | Supervisors | Workers |

|---|---|---|---|---|

| Lump Sum | 1 | 2-3 | 5-8 | 50-100 |

| Item Rate | 1 | 3-4 | 6-10 | 60-120 |

| EPC | 2-3 | 8-12 | 15-25 | 200-500 |

Deliverables at Each Stage

Pre-Construction Phase

Lump Sum Contracts:

- Reports: Detailed project estimates, risk assessment

- Checklists: Scope verification, permit clearances

- Approvals: Building permits, environmental clearances

- Certificates: Insurance policies, bank guarantees

Item Rate Contracts:

- Reports: Preliminary BOQ, site investigation

- Checklists: Rate analysis verification

- Approvals: Technical specifications approval

- Certificates: Vendor pre-qualification certificates

EPC Contracts:

- Reports: Feasibility studies, detailed project reports

- Checklists: Technology selection, vendor evaluation

- Approvals: Design approvals, statutory clearances

- Certificates: Technology licensing agreements

Construction Phase

Key Deliverables:

- Weekly progress reports with photo documentation

- Quality test certificates for materials

- Safety audit reports and compliance certificates

- Monthly billing and measurement sheets

- Change order documentation and approvals

Impact Assessment: Each deliverable directly impacts project timeline, cost, and quality. Delayed approvals can cause 10-15% cost escalation and 20-30% schedule delays.

Post-Construction Phase

Final Deliverables:

- Completion certificates from local authorities

- As-built drawings and O&M manuals

- Warranty documents and maintenance schedules

- Final accounts and project closure reports

- Handover certificates and possession documents

Stakeholders and Communication Matrix

Key Players and Their Roles

Primary Stakeholders:

- Owner/Client: Project vision and funding

- Main Contractor: Overall project execution

- Architect/Consultant: Design and supervision

- Government Authorities: Regulatory compliance

- Subcontractors: Specialized work execution

Secondary Stakeholders:

- Financial institutions and lenders

- Material suppliers and vendors

- Local communities and residents

- Utility service providers

Communication Protocols

Meeting Schedule:

- Daily: Site coordination meetings

- Weekly: Progress review with client

- Monthly: Stakeholder review meetings

- Quarterly: Board-level progress presentations

Reporting Structure:

- Site engineers → Project manager → Client

- Subcontractors → Main contractor → Consultant

- Quality team → Project manager → Client representative

Communication Tools:

- Project management software (Primavera, MS Project)

- Mobile apps for site reporting

- Video conferencing for remote coordination

- Digital document management systems

Value Engineering Opportunities

Cost-Saving Techniques

Design Optimization:

- Alternative Materials: Fly ash bricks instead of clay bricks (15-20% cost saving)

- Structural Optimization: Post-tensioned slabs reducing steel consumption by 10-15%

- MEP Integration: Coordinated services reducing floor height requirements

Construction Methods:

- Precast Construction: 20-30% time saving, 10-15% cost reduction

- Modular Construction: Factory-built components with quality control

- Lean Construction: Waste reduction and efficiency improvement

Sustainable Alternatives

Green Building Materials:

- Recycled steel and concrete aggregates

- Energy-efficient building envelope systems

- Water-efficient plumbing fixtures and systems

- Solar panels and renewable energy integration

Environmental Benefits:

- 30-40% reduction in construction waste

- 20-30% energy savings in building operations

- Carbon footprint reduction by 25-35%

- IGBC/LEED certification potential

Cost-Benefit Analysis:

| Sustainable Feature | Initial Cost Premium | Payback Period | Long-term Savings |

|---|---|---|---|

| Solar Panels | 15-20% | 5-7 years | 60-70% electricity cost |

| Rainwater Harvesting | 3-5% | 2-3 years | 40-50% water cost |

| Energy-Efficient Windows | 8-12% | 4-5 years | 25-30% cooling cost |

Case Study: Real-World Implementation

Project Overview: Metro Station Development

Project Details:

- Location: Gurgaon, Haryana

- Contract Type: EPC Contract

- Contract Value: ₹450 Crores

- Duration: 36 months

- Scope: Design and construction of 3 metro stations with connecting tunnels

Challenges Faced

Technical Challenges:

- Underground Utilities: Existing water and gas pipelines requiring relocation

- Soil Conditions: Unexpected rocky strata increasing excavation costs

- Traffic Management: Construction in busy commercial area

Commercial Challenges:

- Cost Escalation: 18% increase due to material price rise

- Payment Delays: 2-month delay in milestone payments

- Scope Changes: Additional safety features mandated by authorities

Solutions Implemented

Technical Solutions:

- 3D Ground Penetrating Radar: Accurate utility mapping before excavation

- Controlled Blasting: Specialized techniques for rock excavation

- Phased Construction: Minimizing traffic disruption through sequenced work

Commercial Solutions:

- Price Escalation Clause: Automatic adjustment for material cost increases

- Escrow Account: Ensuring timely payment releases

- Change Order Management: Structured process for scope variations

Results and Key Takeaways

Project Outcomes:

- Time Performance: Completed 2 months ahead of schedule

- Cost Performance: Final cost within 5% of revised budget

- Quality Achievement: Zero safety incidents, IGBC Gold certification

Key Learnings:

- Risk Assessment: Comprehensive geotechnical investigation crucial for underground projects

- Stakeholder Management: Regular coordination with traffic police and local authorities

- Technology Adoption: BIM modeling reduced design conflicts by 60%

- Payment Security: Escrow arrangements improved cash flow management

Risks and Mitigation Strategies

Common Risks by Contract Type

Lump Sum Contract Risks:

- Cost Overruns: Contractor bears the risk of cost escalation

- Scope Creep: Additional work requests affecting profitability

- Design Errors: Incomplete drawings leading to variations

Mitigation Strategies:

- Detailed Specifications: Clear scope definition and exclusions

- Contingency Planning: 5-10% buffer for unforeseen costs

- Design Review: Thorough checking before construction start

- Change Order Process: Structured mechanism for scope changes

Item Rate Contract Risks:

- Quantity Variations: Significant differences from estimated quantities

- Rate Disputes: Disagreements on measurement and rates

- Payment Delays: Approval bottlenecks in measurement process

Mitigation Strategies:

- Accurate Surveys: Detailed site investigation for quantity estimation

- Joint Measurement: Regular measurements with client representatives

- Digital Tools: Electronic measurement and approval systems

- Rate Analysis: Transparent rate breakdown and justification

EPC Contract Risks:

- Technology Risks: Performance guarantees and technical failures

- Interface Risks: Coordination between design and construction teams

- Single Point Failure: Contractor default affecting entire project

Mitigation Strategies:

- Proven Technology: Use of established and tested systems

- Integrated Teams: Cross-functional project teams

- Financial Security: Performance guarantees and insurance coverage

- Milestone-based Payments: Risk distribution across project phases

Risk Assessment Tools

Quantitative Risk Analysis:

- Monte Carlo simulation for cost and schedule risks

- Sensitivity analysis for key project parameters

- Decision tree analysis for major project decisions

Qualitative Risk Assessment:

- Risk probability and impact matrix

- Expert judgment and historical data analysis

- Regular risk review and update processes

Financial and Legal Considerations

GST Implications

Tax Treatment by Contract Type:

- Lump Sum: 12% GST on total contract value

- Item Rate: GST applicable on each measured item

- EPC: Different GST rates for design (18%) and construction (12%)

Input Tax Credit:

- Materials: Full ITC available for registered contractors

- Services: ITC subject to specific conditions and restrictions

Bank Guarantees and Securities

Performance Guarantee Requirements:

- Lump Sum: 5-10% of contract value

- Item Rate: 5% of estimated contract value

- EPC: 10-15% due to higher risks

Other Securities:

- Advance Payment Guarantee: 100% of advance amount

- Retention Money: 5-10% of running payments

- Warranty Guarantee: 2-5% for defect liability period

RERA Compliance for Residential Projects

Mandatory Requirements:

- Registration of projects above 500 sq.m or 8 apartments

- Separate escrow account for project funds

- Quarterly progress and financial reports

- Completion within registered timeline

Impact on Contract Selection:

- Preference for lump sum contracts for cost certainty

- Detailed project schedules with milestone payments

- Quality certifications and completion guarantees

Contract Selection Framework

Decision Matrix for Contract Type Selection

Project Characteristics Analysis:

| Factor | Lump Sum | Item Rate | EPC |

|---|---|---|---|

| Scope Definition | Well-defined | Partially defined | Conceptual |

| Budget Certainty | High | Medium | High |

| Timeline Pressure | Medium | Low | High |

| Technical Complexity | Low-Medium | Medium | High |

| Client Involvement | Low | High | Low |

Selection Guidelines:

Lump Sum When:

- Project scope is clearly defined with complete drawings

- Budget constraints require cost certainty

- Client prefers minimal involvement in day-to-day management

- Risk of scope changes is low

Item Rate When:

- Project quantities are uncertain or variable

- Flexibility needed for design changes during construction

- Detailed supervision and measurement systems are available

- Long-duration projects with potential for rate revisions

EPC When:

- Fast-track project delivery is required

- Single-point responsibility is preferred

- Complex technical systems are involved

- Client lacks technical expertise for project management

Risk-Return Analysis

Risk Distribution:

| Risk Category | Lump Sum (Contractor) | Item Rate (Shared) | EPC (Contractor) |

|---|---|---|---|

| Design Risk | Medium | Low | High |

| Construction Risk | High | Medium | High |

| Cost Risk | High | Low | High |

| Schedule Risk | Medium | Medium | High |

| Performance Risk | Medium | Low | High |

Future Trends in Construction Contracts

Digital Transformation

Smart Contracts and Blockchain:

- Automated milestone payments based on IoT sensors

- Transparent payment processing without intermediaries

- Immutable project records and documentation

- Reduced disputes through automated compliance checking

Artificial Intelligence Applications:

- Predictive risk analysis using historical project data

- Automated contract review and red-flag identification

- Intelligent scheduling and resource optimization

- Real-time project monitoring and early warning systems

Sustainable Construction Contracts

Performance-Based Contracts:

- Energy performance guarantees for building operations

- Carbon footprint reduction targets with penalties/incentives

- Water conservation and waste reduction requirements

- Green building certification as contract deliverable

Circular Economy Integration:

- Material recycling and reuse requirements

- Waste-to-energy conversion specifications

- Biodegradable material preferences

- End-of-life building deconstruction planning

Technology Integration Trends

Building Information Modeling (BIM):

- Mandatory BIM adoption in government projects

- 4D scheduling and 5D cost integration

- Clash detection and design optimization

- Virtual reality for client approvals

IoT and Smart Construction:

- Sensor-based quality monitoring

- Real-time equipment tracking and maintenance

- Worker safety monitoring systems

- Environmental condition monitoring

Conclusion

Understanding construction contract types is fundamental to successful project delivery in India’s dynamic construction industry. Each contract type – Lump Sum, Item Rate, and EPC – serves specific project needs and risk profiles:

Key Takeaways:

- Lump Sum contracts offer budget certainty but require detailed planning and risk assessment

- Item Rate contracts provide flexibility but need robust measurement and supervision systems

- EPC contracts enable fast-track delivery but require careful contractor selection and monitoring

Success Factors:

- Thorough Planning: Detailed project analysis before contract type selection

- Risk Management: Comprehensive risk assessment and mitigation strategies

- Stakeholder Alignment: Clear communication and expectation management

- Technology Adoption: Leveraging digital tools for better project outcomes

- Legal Compliance: Adherence to RERA, GST, and other regulatory requirements

Future Outlook: The construction industry is evolving towards more integrated, technology-driven, and sustainable contracting approaches. Smart contracts, AI-powered project management, and performance-based sustainability metrics will reshape how construction projects are conceived and delivered.