Introduction

The success of any construction project—whether it’s a simple home renovation or a complex high-rise development—largely depends on selecting the right contractor. This phase, commonly known as tendering and contractor finalization, forms a crucial link in the project lifecycle that can make or break your construction endeavor.

In India’s diverse construction landscape, understanding this process is essential for stakeholders at all levels: from first-time homebuilders to seasoned developers managing large-scale commercial projects. This blog post aims to demystify the tendering process, breaking down complex procedures into digestible information that benefits everyone involved in construction projects.

Understanding the Tendering Process

What is Tendering?

Tendering is a structured process of inviting and selecting qualified contractors to execute construction works at competitive prices while ensuring quality standards are met. It creates a transparent, fair environment for competition among potential contractors while giving project owners the best value for their investment.

Why is Proper Tendering Important?

- Financial Protection: Ensures competitive pricing and prevents cost overruns

- Quality Assurance: Sets clear standards and expectations for workmanship

- Risk Management: Distributes project risks appropriately between parties

- Legal Compliance: Ensures adherence to regulatory requirements

- Time Efficiency: Establishes realistic timelines and avoids delays

Types of Tendering Systems in Indian Construction

The Indian construction industry typically follows these tendering methods:

1. Open Tendering (Public Tendering)

What: Invites all interested contractors to bid through public advertisements.

Best suited for: Government projects, public works, and projects requiring maximum transparency.

Advantages:

- Maximum competition ensuring competitive rates

- Transparency in selection process

- Equal opportunity for all contractors

Disadvantages:

- Time-consuming evaluation process

- Higher administrative burden

- Potential for unqualified bidders

2. Selective Tendering (Limited Tendering)

What: Invites only pre-qualified or shortlisted contractors to submit bids.

Best suited for: Private projects, specialized works requiring specific expertise.

Advantages:

- Quality control through pre-qualification

- More manageable evaluation process

- Higher likelihood of competent contractors

Disadvantages:

- Limited competition

- Potential for favoritism

- Less transparency than open tendering

3. Negotiated Tendering

What: Direct negotiation with one or few selected contractors without formal competitive bidding.

Best suited for: Emergency works, highly specialized projects, or extensions of existing contracts.

Advantages:

- Speed of appointment

- Flexibility in terms and conditions

- Works well for urgent requirements

Disadvantages:

- Limited price competition

- Less transparency

- Potential for higher costs

4. Two-Stage Tendering

What: Initially evaluates technical proposals, followed by financial bids from shortlisted contractors.

Best suited for: Complex projects requiring specialized technical expertise.

Advantages:

- Balance between technical quality and cost

- Detailed assessment of contractor capabilities

- Better alignment of expectations

Disadvantages:

- Longer selection process

- More complex evaluation

The Complete Tendering Process Workflow

Stage 1: Pre-Tender Planning

Key Activities:

Project scope definition

- Finalizing drawings and specifications

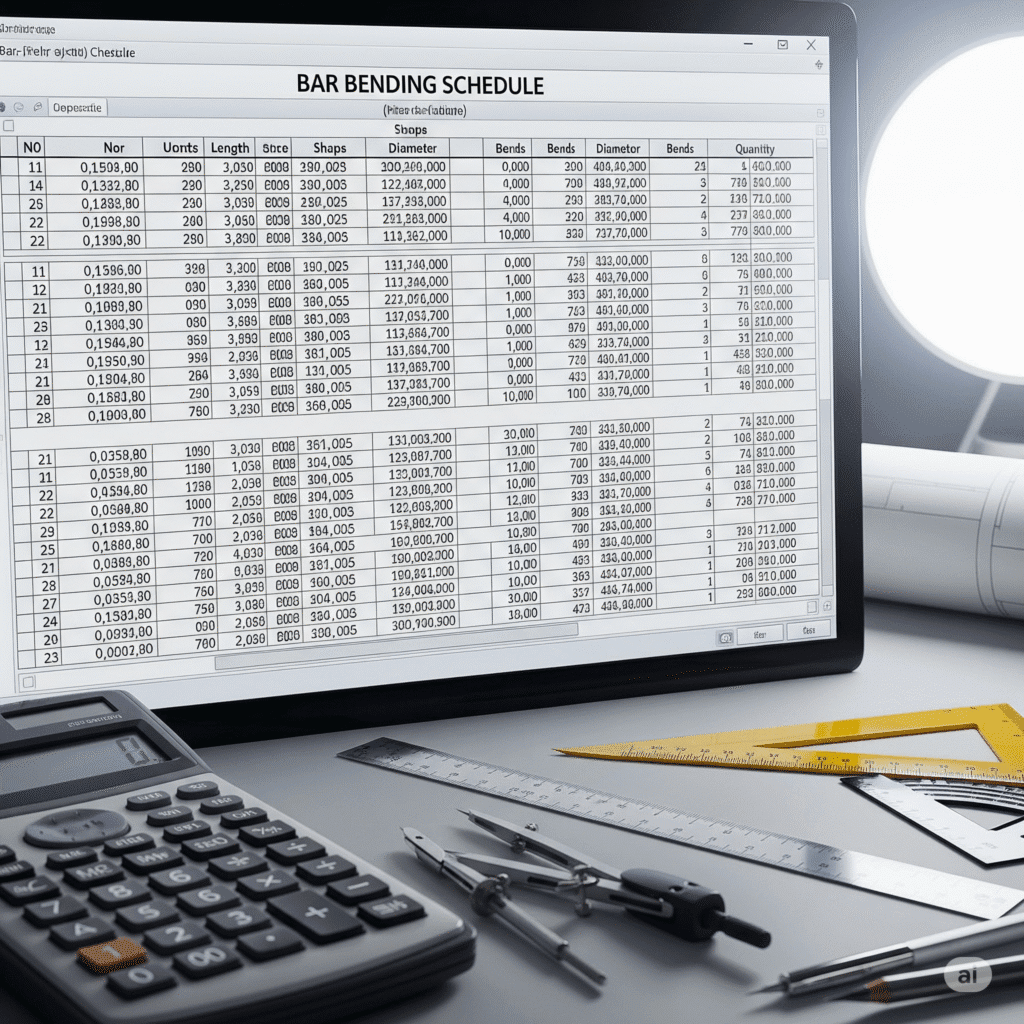

- Preparing detailed Bill of Quantities (BOQ)

- Setting quality standards

Budget estimation

- Developing preliminary cost estimates

- Setting contingency allowances

- Establishing cost benchmarks

Tender strategy development

- Determining appropriate tender type

- Setting evaluation criteria

- Establishing timeline for tender process

Stakeholders Involved:

- Project Owner/Developer

- Project Management Consultant (PMC)

- Architects

- Structural Engineers

- MEP Consultants

- Quantity Surveyors

Communication Matrix:

| Stakeholder | Communicates With | Frequency | Communication Mode |

|---|---|---|---|

| Project Owner | All consultants | Weekly | Meetings, emails |

| PMC | All stakeholders | Daily | Reports, meetings |

| Consultants | PMC, other consultants | As required | Technical discussions |

| Quantity Surveyor | PMC, Architects, Engineers | Regular | BOQ reviews, cost estimates |

Stage 2: Tender Document Preparation

Key Activities:

Compilation of tender documents including:

- Invitation to Tender (ITT)

- Instructions to Bidders

- General and Special Conditions of Contract

- Technical Specifications

- Drawings

- Bill of Quantities (BOQ)

- Schedule of Rates

- Form of Tender

Legal and technical review

- Contract terms verification

- Compliance with regulations

- Technical accuracy check

Material Requirements:

- Comprehensive drawings set (architectural, structural, MEP)

- Technical specifications

- Detailed BOQ templates

- Standard contract forms (preferably aligned with FIDIC or Indian standard contracts)

Applicable Standards:

- IS 7238: Guide for preparation of tender documents for construction

- IS 3861: Method of measurement of civil engineering works

- NBC 2016: National Building Code of India provisions

Stage 3: Tender Advertisement and Invitation

Key Activities:

Publication of tender notice

- Newspaper advertisements (for public tenders)

- Industry publications

- E-procurement platforms

- Direct invitations to selected contractors

Pre-qualification process (if applicable)

- Technical capability assessment

- Financial stability verification

- Past experience evaluation

- Resource availability check

Typical Pre-qualification Criteria:

- Minimum years of experience (typically 5-10 years)

- Similar project execution experience

- Minimum annual turnover (often 30-100% of estimated project cost)

- Positive net worth

- Available bid capacity

- Quality certifications (ISO 9001, ISO 14001, etc.)

- Safety records

Checklist for Contractor Pre-qualification:

- Company registration documents

- GST registration

- PAN card details

- Income tax returns (last 3 years)

- Audited balance sheets (last 3 years)

- Bank solvency certificate

- Experience certificates for similar works

- Equipment ownership/leasing details

- Key personnel CVs

- Quality management system certifications

- Safety policy and records

- Ongoing projects list with status

Stage 4: Pre-Bid Meeting and Clarifications

Key Activities:

Conducting pre-bid meetings

- Explaining project scope

- Clarifying technical requirements

- Addressing contractor queries

Site visits for prospective bidders

- Physical examination of site conditions

- Understanding access and logistics

- Identifying potential challenges

Issuing addenda/corrigenda if required

- Modifications to tender documents

- Additional information provision

- Timeline extensions if necessary

Best Practices:

- Record all queries and responses in writing

- Share clarifications with all bidders

- Document site visit observations

- Maintain transparency in information sharing

Stage 5: Bid Submission and Opening

Key Activities:

Receipt of technical and financial bids

- Sealed envelope submission

- E-procurement platform submission

- Two-packet system (technical and financial bids separated)

Public bid opening (for transparency)

- Recording attendees

- Documenting submitted bids

- Reading out key information

Requirements for Valid Bid Submission:

- Earnest Money Deposit (EMD)/Bid Security

- Signed tender documents

- Completed forms and schedules

- Power of attorney for signing authority

- Joint venture agreement (if applicable)

- Technical proposal with methodology

- Financial bid in prescribed format

Stage 6: Bid Evaluation

Technical Evaluation:

Compliance check

- Verification of all required documents

- Validation of eligibility criteria

- Assessment of deviations

Technical scoring (if applicable)

- Methodology assessment

- Resource planning review

- Timeline feasibility

- Innovation and value addition

Financial Evaluation:

Arithmetic check

- Verification of calculations

- Correction of arithmetic errors

- Analysis of unit rates

Comparative analysis

- Preparation of comparative statements

- Identification of outliers (abnormally low or high bids)

- Value for money assessment

Loading of financial implications of deviations

- Quantifying the cost of non-compliance

- Adjusting bid amounts for fair comparison

Evaluation Methods Commonly Used:

Least Cost Selection (LCS):

- Awards to the lowest financial bidder among technically qualified contractors

- Common for standardized works with well-defined specifications

Quality and Cost Based Selection (QCBS):

- Combines technical and financial scores with predetermined weightages

- Typically uses formula: Final Score = (0.7 × Technical Score) + (0.3 × Financial Score)

- Suitable for complex projects requiring specialized expertise

Value-Based Selection:

- Considers lifecycle costs, not just initial bid amount

- Incorporates operational efficiency, durability, and maintenance costs

- Increasingly adopted for sustainable construction projects

Stage 7: Negotiation and Contractor Finalization

Key Activities:

Negotiations with selected bidder(s)

- Rate rationalization

- Scope clarification

- Timeline confirmation

- Terms and conditions finalization

Due diligence

- Financial stability re-verification

- Resource availability confirmation

- References check

Contract award recommendation

- Preparation of award recommendation

- Justification for selection

- Approval from competent authority

Best Practices During Negotiation:

- Focus on win-win outcomes

- Document all agreed changes

- Maintain ethical standards

- Avoid substantial scope changes

- Keep negotiations time-bound

Stage 8: Contract Award and Mobilization

Key Activities:

Letter of Intent (LOI) / Letter of Award (LOA) issuance

- Formal communication of award

- Outline of key terms and conditions

- Timeline for contract signing

Contract signing

- Preparation of contract documents

- Verification of performance security

- Execution of agreement

Mobilization initiation

- Site handover

- Resource deployment

- Work plan finalization

Key Contract Documents:

- Signed agreement

- General and Special Conditions of Contract

- Specifications and Drawings

- Agreed Bill of Quantities

- Work schedule

- Performance security

- Insurance certificates

Value Engineering Opportunities

Value engineering in the tendering and contractor selection process can yield significant benefits. Here are key opportunities at different stages:

Tender Document Preparation:

- Performance Specifications: Instead of prescriptive specifications, use performance-based requirements to allow contractors to propose innovative solutions

- Alternative Materials Clause: Include provisions for contractors to suggest alternative materials that meet or exceed specified performance

- Incentive Mechanisms: Incorporate shared savings clauses for cost-reduction ideas

Pre-Bid Meeting:

- Innovation Workshop: Conduct specialized sessions encouraging bidders to suggest value-adding alternatives

- Early Contractor Involvement: Allow preliminary input from potential bidders on constructability issues

Bid Evaluation:

- Value-Added Proposals: Request bidders to submit optional value engineering proposals alongside their primary bid

- Life-Cycle Cost Analysis: Evaluate bids on total cost of ownership rather than just initial cost

Negotiation:

- Value Engineering Workshop: Conduct focused sessions with the preferred bidder to identify cost-saving opportunities

- Target Value Design: Set collaborative cost targets and work with the selected contractor to achieve them

Case Study: Residential High-Rise Project in Pune

Project Overview:

- Type: 25-story luxury residential tower

- Built-up Area: 35,000 sq.m.

- Estimated Cost: ₹175 crores

- Location: Koregaon Park, Pune

Challenge:

The developer faced significant market pressure to complete the project within 24 months while maintaining premium quality standards. The project involved complex structural requirements and high-end finishes, requiring specialized expertise.

Approach:

The project management consultant implemented a two-stage tendering process:

Stage 1 (Technical Pre-qualification):

Rigorous pre-qualification criteria were established, requiring:

- Minimum 10 years of experience in high-rise construction

- Completion of at least 3 similar projects in the last 7 years

- Annual turnover of ₹200 crores

- Quality certifications including ISO 9001, 14001, and 45001

Technical evaluation criteria included:

- Construction methodology (30 points)

- Project team qualifications (25 points)

- Equipment resources (15 points)

- Quality management systems (15 points)

- Safety record (15 points)

Stage 2 (Financial Bid):

- Only contractors scoring above 75% in technical evaluation were invited to submit financial bids

- A detailed BOQ with over 1,200 line items was provided

- Bidders were required to submit their construction schedule with resource loading

Value Engineering Implementation:

- Bidders were explicitly invited to submit value engineering proposals

- The tender included a shared savings clause (70% for client, 30% for contractor)

- A one-week value engineering workshop was conducted with the shortlisted bidder

Results:

- Time Savings: The selected contractor proposed an alternative formwork system that reduced the floor cycle time from 12 days to 8 days

- Cost Reduction: Value engineering proposals resulted in ₹4.5 crore savings (approximately 2.5% of project cost)

- Quality Enhancement: The contractor’s specialized experience allowed for better execution of complex architectural features

- Successful Completion: The project was completed 1 month ahead of schedule with zero major quality issues

Key Learnings:

- Thorough pre-qualification ensured only capable contractors participated

- Two-stage tendering balanced technical expertise with competitive pricing

- The value engineering workshop yielded significant benefits

- Clear evaluation criteria led to transparent selection

- Early contractor involvement improved constructability

Best Practices and Common Pitfalls

Best Practices:

1. Comprehensive Tender Documentation

- Invest time in detailed and accurate tender documents

- Include clear scope definition and performance requirements

- Provide complete technical specifications and drawings

2. Realistic Timelines

- Allow adequate time for bid preparation (typically 3-4 weeks)

- Set realistic project execution timelines

- Include buffer for unforeseen circumstances

3. Transparent Evaluation Process

- Establish clear evaluation criteria before tender issue

- Document the evaluation process thoroughly

- Maintain confidentiality of commercial information

4. Effective Communication

- Respond to bidder queries promptly and clearly

- Ensure all bidders receive identical information

- Document all communications formally

Common Pitfalls:

1. Incomplete Tender Documentation

- Issue: Missing or conflicting information in tender documents

- Impact: Multiple queries, addenda, and potential disputes

- Solution: Thorough review by all technical disciplines before issue

2. Unrealistic Cost Estimates

- Issue: Significant deviation between estimate and received bids

- Impact: Budget overruns or need to re-tender

- Solution: Market-based estimating and regular cost database updates

3. Inadequate Technical Specifications

- Issue: Vague or insufficient technical requirements

- Impact: Quality issues, disputes, and claims

- Solution: Detailed, performance-based specifications with clear acceptance criteria

4. Over-emphasis on Lowest Price

- Issue: Selecting contractors solely on lowest bid amount

- Impact: Quality compromises, delays, and potential contractor failure

- Solution: Balanced evaluation considering technical capability, experience, and financial stability

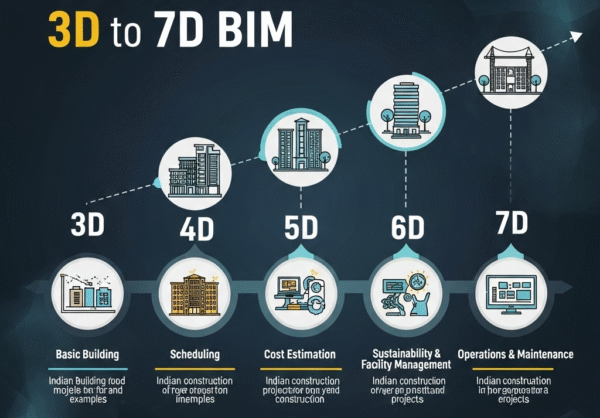

Digital Transformation in Tendering

The construction industry in India is increasingly adopting digital tools for tendering:

E-Procurement Platforms

- Government e-Marketplace (GeM)

- Central Public Procurement Portal (CPPP)

- State-specific e-procurement portals

- Private platforms like BuildSupply and eProcure

Benefits of Digital Tendering:

- Increased transparency

- Wider contractor participation

- Reduced paperwork

- Streamlined evaluation

- Better data analytics

- Reduced tender cycle time

Implementation Challenges:

- Digital literacy among contractors

- Technical infrastructure requirements

- Cybersecurity concerns

- Initial implementation costs

Conclusion

The tendering and contractor finalization process represents a pivotal moment in the project lifecycle. When executed thoughtfully, it sets the foundation for successful project delivery by selecting the right partner with the right capabilities at the right price.

For first-time homebuilders, understanding this process helps in making informed decisions when selecting contractors. For professionals and developers, mastering the nuances of tendering can lead to significant improvements in project outcomes through better contractor selection and value engineering.

In the evolving construction landscape of India, embracing best practices in tendering—while leveraging digital transformation opportunities—can dramatically improve project delivery success rates and stakeholder satisfaction.

References

- National Building Code of India, 2016

- IS 7238: Guide for preparation of tender documents for construction

- IS 3861: Method of measurement of civil engineering works

- FIDIC Conditions of Contract for Construction, 2017

- Construction Industry Development Council (CIDC) guidelines

- Manual for Procurement of Works, Ministry of Finance, Government of India