Introduction

Construction sites are among the most hazardous work environments, with workers facing risks from heights, heavy machinery, electrical systems, and structural collapses. Every year, thousands of construction workers suffer injuries or fatalities that could have been prevented with proper safety measures. As an engineer, contractor, or project manager, ensuring construction site safety isn’t just a legal obligation—it’s a moral responsibility that protects lives and prevents costly project delays.

This comprehensive guide covers essential safety measures that every construction professional must understand and implement. Whether you’re a fresh engineering graduate starting your first project, an experienced developer managing multiple sites, or a homeowner planning to build your dream house, this article will equip you with the knowledge to maintain the highest safety standards.

Who Should Read This:

- Civil engineers and construction managers

- Real estate developers and investors

- Architects and structural consultants

- Construction workers and supervisors

- Homeowners planning construction projects

- Engineering students working on project reports

- Safety officers and compliance managers

Key Methodologies & Processes

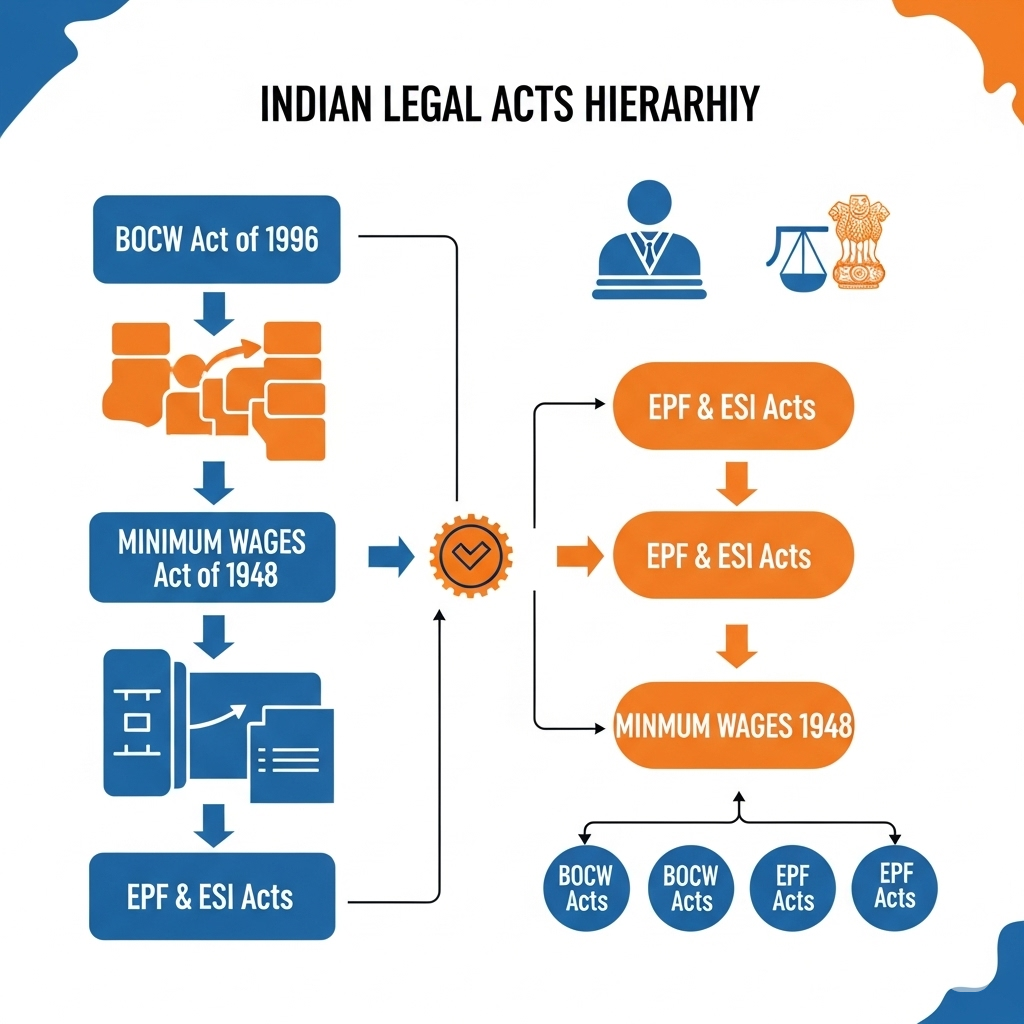

Regulatory Compliance Framework

BOCW Act 1996 Mandates The Building and Other Construction Workers Act 1996 forms the backbone of construction safety in India. Key requirements include:

- Registration of all construction workers in government databases

- Mandatory welfare provisions including first aid facilities, drinking water, and rest areas

- Appointment of safety officers for sites with more than 500 workers

- Regular safety training and awareness programs

IS 15883 PPE Standards Personal Protective Equipment must meet rigorous testing protocols:

- Safety helmets tested for impact resistance (430 joules) and penetration

- Safety harnesses with breaking strength of 15kN minimum

- Safety footwear with 200-joule toe protection and slip-resistant soles

- Cut-resistant gloves rated for specific hazard levels

NBC 2016 Fire Safety Norms National Building Code mandates:

- Clear exit routes with minimum 1.8m width for every 40 occupants

- Fire extinguisher placement every 30m with appropriate class ratings

- Emergency lighting systems with 90-minute backup power

- Fire assembly points at safe distances from structures

Structural Safety Protocols

Shoring & Underpinning Checks Protection of adjacent buildings during excavation requires:

- Soil investigation reports before deep excavations

- Continuous monitoring of nearby structures for settlement

- Installation of inclinometers and crack monitoring systems

- Immediate notification protocols for structural distress

Formwork Load Calculations Following IS 14687 standards:

- Design loads including concrete weight, construction loads, and wind loads

- Safety factors of 2.5 for temporary structures

- Daily inspection checklists for formwork alignment and stability

- Certified calculations by structural engineers

Electrical Safety Implementation

IS 3043 Earthing Compliance Electrical safety requires:

- Earth resistance testing maintaining <5Ω for all equipment

- Monthly testing of earth leakage circuit breakers

- Proper earthing of all metal scaffolding and temporary structures

- Installation of residual current devices (RCDs) for portable equipment

Lockout-Tagout (LOTO) Procedures Six-step isolation process:

- Preparation and planning

- Equipment shutdown

- Isolation of energy sources

- Lockout/tagout application

- Verification of isolation

- Safe work completion and restoration

Material & Manpower Requirements

Essential Safety Materials

Personal Protective Equipment

- Safety helmets (IS 2925): 1 per worker plus 10% spare

- Safety harnesses (IS 3521): For all height work above 2m

- Safety boots (IS 15298): Steel toe caps with puncture-resistant soles

- High-visibility vests: Fluorescent colors with reflective strips

- Respiratory protection: P100 filters for silica dust environments

Safety Infrastructure

- Safety nets (IS 11057): For debris containment and fall protection

- Guardrails: 1.2m height with intermediate rails and toe boards

- Safety signs (IS 9457): Multilingual warning, mandatory, and prohibition signs

- Fire safety equipment: ABC type extinguishers, sand buckets, fire blankets

- First aid supplies: Bandages, antiseptics, emergency medications

Manpower Requirements

Safety Personnel Structure

- Site Safety Officer: 1 per 500 workers (BOCW Act requirement)

- Safety Supervisors: 1 per 100 workers for high-risk activities

- First Aid Personnel: 1 trained medic per 150 workers

- Emergency Response Team: 5% of total workforce trained in evacuation procedures

Training Requirements

- Induction training: 8 hours for new workers

- Toolbox talks: Daily 15-minute safety briefings

- Specialized training: 40 hours for equipment operators

- Refresher training: Quarterly updates on safety procedures

Deliverables at Each Stage

Pre-Construction Stage

Safety Planning Documents

- Site-specific Safety Plan including hazard identification and risk assessment

- Emergency Response Plan with evacuation routes and assembly points

- Construction Health and Safety File as per local regulations

- Method Statements for high-risk activities (excavation, working at height)

Inspection Checklists

- Site condition assessment covering ground stability and access routes

- Utility location survey preventing underground service strikes

- Environmental impact assessment for dust, noise, and waste management

- Welfare facility inspection ensuring adequate sanitation and rest areas

Approvals and Permits

- Building permit with approved safety measures

- Environmental clearance for projects above specified thresholds

- Fire safety clearance from local fire department

- Electrical safety certificate for temporary installations

Construction Stage

Daily Safety Deliverables

- Morning safety briefings with toolbox talk records

- Daily inspection reports for scaffolding, formwork, and equipment

- PPE compliance audit sheets with photographic evidence

- Incident reporting forms for near-misses and accidents

Weekly Safety Reviews

- Safety performance metrics including leading and lagging indicators

- Equipment maintenance logs with safety-critical item focus

- Training records update with skill competency assessments

- Safety committee meeting minutes with action item tracking

Monthly Compliance Reports

- Regulatory compliance audit with corrective action plans

- Safety statistics analysis identifying trends and patterns

- Contractor safety performance evaluation with scoring

- Third-party safety audit findings and implementation status

Post-Construction Stage

Final Safety Documentation

- As-built safety drawings showing permanent safety installations

- Equipment handover certificates with safety operation manuals

- Safety training records for building maintenance personnel

- Emergency procedure documentation for facility management

Compliance Certificates

- Fire safety certificate from local authorities

- Electrical safety clearance for permanent installations

- Structural safety certificate from approved engineers

- Environmental compliance certificate for project completion

Stakeholders & Communication Matrix

Key Stakeholders

Primary Stakeholders

- Project Owner/Developer: Ultimate responsibility for safety culture and resource allocation

- Main Contractor: Day-to-day safety implementation and workforce management

- Safety Consultant: Independent safety oversight and regulatory compliance

- Local Authorities: Regulatory enforcement and permit approvals

Secondary Stakeholders

- Subcontractors: Specialized trade safety compliance

- Material Suppliers: Safety data sheets and handling instructions

- Insurance Companies: Risk assessment and claims management

- Community Representatives: Addressing public safety concerns

Communication Protocols

Daily Communications

- Morning safety huddles with all trades present

- Real-time safety alerts through mobile messaging systems

- Incident notification within 2 hours to all stakeholders

- End-of-shift safety performance summary

Weekly Reporting

- Safety committee meetings with rotating trade representation

- Progress reports including safety KPIs and trend analysis

- Corrective action status updates with completion timelines

- Training schedule coordination across all subcontractors

Monthly Strategic Reviews

- Safety performance dashboard presentation to senior management

- Regulatory compliance status review with legal implications

- Safety budget performance against allocated resources

- Long-term safety culture development initiatives

Value Engineering Opportunities

Cost-Effective Safety Solutions

Technology Integration

- AI-powered surveillance cameras for real-time PPE compliance monitoring reduce manual inspection costs by 40%

- Smart sensors for structural monitoring provide early warning systems preventing costly emergency interventions

- Digital safety management platforms eliminate paper-based processes and improve data accuracy

- Virtual reality training reduces traditional training costs while improving retention rates

Preventive Maintenance Programs

- Scheduled equipment maintenance prevents costly breakdowns and safety incidents

- Predictive analytics identify potential safety hazards before they become critical

- Standardized safety procedures across multiple projects reduce training and implementation costs

- Energy-efficient safety lighting systems reduce operational costs over project lifecycle

Sustainable Safety Practices

Green Safety Materials

- Recycled plastic safety barriers offer durability with environmental benefits

- Solar-powered safety lighting systems eliminate electrical installation costs

- Biodegradable spill containment materials reduce environmental cleanup costs

- Reusable safety signage systems with interchangeable messaging reduce waste

Resource Optimization

- Modular safety systems allow reuse across multiple project phases

- Bulk procurement of safety equipment achieves economies of scale

- Shared safety resources among multiple contractors on large projects

- Digital documentation systems eliminate printing and storage costs

Case Study: Mumbai Metro Rail Project – Line 3

Project Overview

The Mumbai Metro Rail Project Line 3 represents one of India’s most challenging underground construction projects, spanning 33.5 kilometers with 27 stations. The project involved complex tunneling operations beneath a densely populated urban area, requiring unprecedented safety measures.

Challenges Faced

Technical Challenges

- Tunneling beneath existing railway lines and high-rise buildings

- Managing groundwater ingress in coastal soil conditions

- Coordinating with 15 different contractors simultaneously

- Working in extremely confined underground spaces

Safety Challenges

- Risk of ground settlement affecting surface structures

- Potential gas accumulation in tunnel sections

- Emergency evacuation from depths of up to 35 meters

- Coordinating safety protocols across multilingual workforce

Solutions Implemented

Advanced Monitoring Systems

- Installation of 500+ ground settlement monitoring points with real-time data transmission

- Automated gas detection systems with immediate alarm capabilities

- CCTV monitoring network covering 100% of underground work areas

- Emergency communication systems with direct connection to surface control rooms

Innovative Safety Measures

- Custom-designed escape capsules for emergency evacuation from tunnel depths

- Redundant ventilation systems with 150% capacity for emergency scenarios

- Advanced tunnel boring machine safety features including automatic shutdown systems

- Specialized rescue equipment positioned every 500 meters along tunnel alignment

Results & Key Takeaways

Safety Performance Achievements

- Zero fatalities over 8 years of construction despite high-risk operations

- 85% reduction in reportable injuries compared to similar international projects

- 99.2% PPE compliance rate maintained throughout project duration

- Emergency response time averaging 3 minutes for any tunnel incident

Lessons Learned

- Investment in advanced safety technology pays for itself through incident prevention

- Multilingual safety communication is critical for diverse workforce management

- Regular emergency drills build confidence and reduce panic during actual emergencies

- Contractor safety performance incentives drive measurable safety improvements

Risks & Mitigation Strategies

Common Construction Safety Risks

Fall-Related Hazards Risk Level: High – Contributing to 35% of construction fatalities

Mitigation Strategies:

- Implement three-point contact rule for all ladder usage

- Install safety nets below all work areas above 3 meters

- Ensure proper harness anchorage points tested to 5000kg strength

- Conduct weekly fall protection equipment inspections with documentation

- Provide platform-specific fall protection training for each work area

Electrical Hazards Risk Level: High – Often resulting in severe injuries or fatalities

Mitigation Strategies:

- Maintain minimum 3-meter clearance from overhead power lines

- Implement lockout-tagout procedures for all electrical work

- Use ground fault circuit interrupters (GFCI) for all temporary electrical installations

- Conduct daily visual inspections of electrical cords and equipment

- Establish electrical permit system for all energized electrical work

Struck-by Incidents Risk Level: Medium-High – Common in material handling operations

Mitigation Strategies:

- Establish exclusion zones around crane operations with physical barriers

- Implement spotting procedures for all vehicle reversing operations

- Secure all materials against wind displacement using appropriate tie-downs

- Provide high-visibility clothing for all personnel in equipment operation areas

- Install backup alarms and warning lights on all mobile equipment

Preventive Risk Management Tools

Technology-Based Solutions

- Wearable sensors monitoring worker vital signs and location

- Predictive analytics identifying high-risk work patterns

- Mobile apps for real-time hazard reporting and resolution tracking

- Drone surveys for remote hazard identification in dangerous areas

Management System Approaches

- Behavior-based safety observation programs with positive reinforcement

- Safety performance incentive systems tied to measurable outcomes

- Regular safety culture assessments with actionable improvement plans

- Cross-functional safety committees with worker representation

Cost vs. Time Analysis Graph

Conclusion & Further Reading

Construction site safety is not just a regulatory requirement—it’s a fundamental responsibility that protects human lives and ensures project success. The comprehensive measures outlined in this guide, from regulatory compliance to emerging technologies, provide a roadmap for creating safer construction environments.

Key takeaways for implementation:

- Start with a robust safety culture that empowers every worker to prioritize safety

- Invest in proper training and equipment—the cost of prevention is always less than the cost of incidents

- Leverage technology and data analytics to identify and mitigate risks proactively

- Maintain open communication channels among all stakeholders

- Continuously monitor and improve safety performance through regular audits and feedback

Remember that safety is an ongoing journey, not a destination. As construction methods evolve and new technologies emerge, safety protocols must adapt accordingly. The goal is zero incidents—a challenging but achievable target when safety becomes ingrained in every aspect of construction operations.

External References

- IS SP:70 Hand book on Construction Safety Practices

- Occupational Safety and Health Administration (OSHA) Guidelines

- International Labour Organization (ILO) Construction Safety Standards

- Indian Green Building Council (IGBC) Sustainable Construction Practices