Introduction

The completion of construction doesn’t mark the end of a project’s journey—it’s merely the beginning of its operational life. Post-construction maintenance and feedback form critical components of the project life cycle that ensure the longevity, functionality, and continuous improvement of built assets. This phase is often overlooked but can significantly impact the return on investment and user satisfaction over time.

In India’s diverse construction landscape—spanning residential buildings (independent homes, group housing, high-rises), commercial complexes, and industrial facilities—proper maintenance practices and feedback systems are essential for preserving asset value and enhancing performance.

This blog explores the methodologies, requirements, stakeholders, and best practices in post-construction maintenance and feedback across various construction projects in India, with special attention to value engineering opportunities that can optimize operations and reduce lifecycle costs.

Post Construction Maintenance and Feedback: The Foundation of Asset Longevity

Key Methodologies in Post Construction Maintenance and Feedback

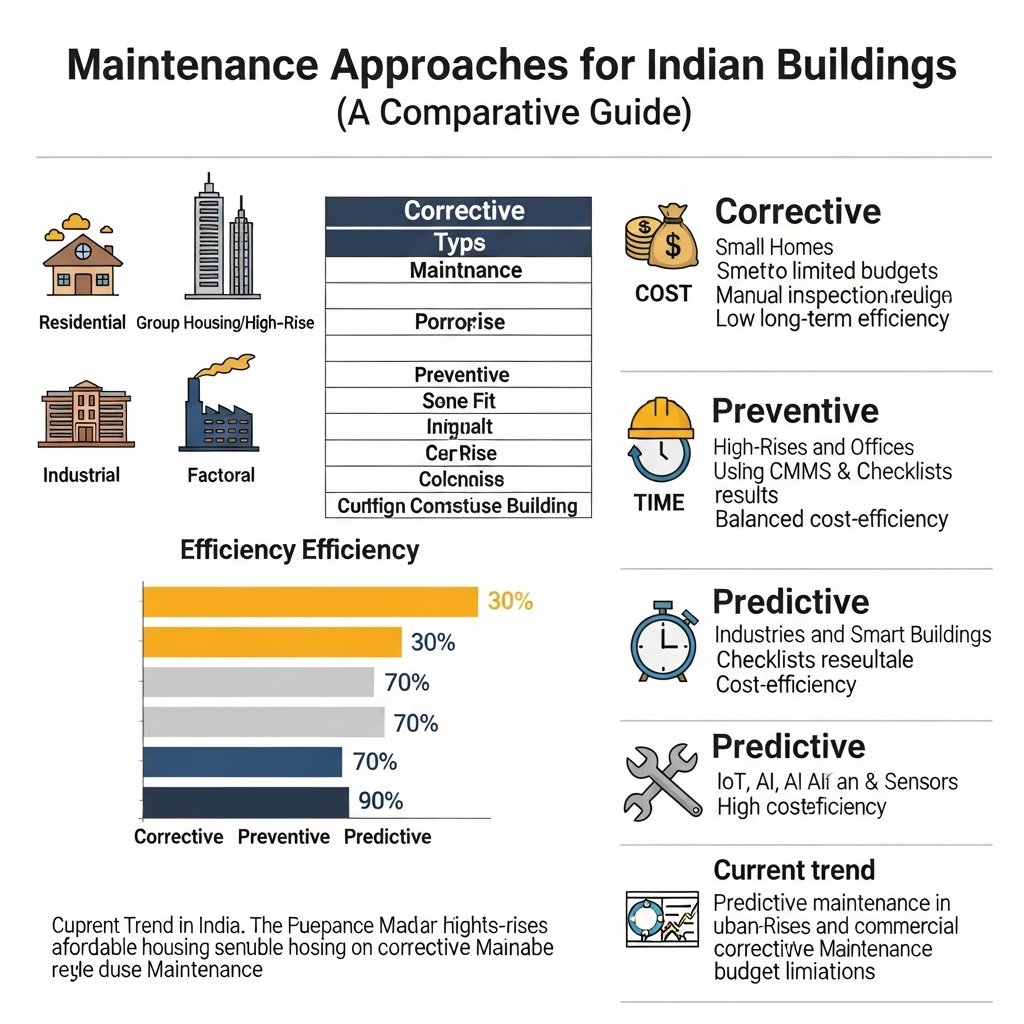

Post-construction maintenance in India typically follows three primary approaches:

- Preventive Maintenance: Scheduled activities performed to prevent failures and extend asset life

- Corrective Maintenance: Actions taken to fix identified defects or breakdowns

- Predictive Maintenance: Data-driven approach to predict and prevent failures before they occur

The implementation of these methodologies varies based on project type:

| Project Type | Common Maintenance Approach |

|---|---|

| Residential (Independent) | Primarily corrective, with some preventive measures |

| Group Housing/High-Rise | Structured preventive and predictive maintenance programs |

| Commercial | Comprehensive preventive and predictive maintenance with detailed scheduling |

| Industrial | Sophisticated predictive maintenance systems with real-time monitoring |

Maintenance Management Systems

Modern projects increasingly implement Computerized Maintenance Management Systems (CMMS) that help schedule, track, and document maintenance activities. This approach is particularly prevalent in large residential complexes, commercial properties, and industrial facilities.

Material and Manpower Requirements

The material and manpower requirements for post-construction maintenance depend significantly on the project scale and complexity:

Materials:

- Replacement components (plumbing fixtures, electrical parts)

- Consumables (lubricants, cleaning agents, paints)

- Specialized repair materials (waterproofing compounds, adhesives)

- Testing equipment and tools

Manpower:

- Facility managers (1 per major property)

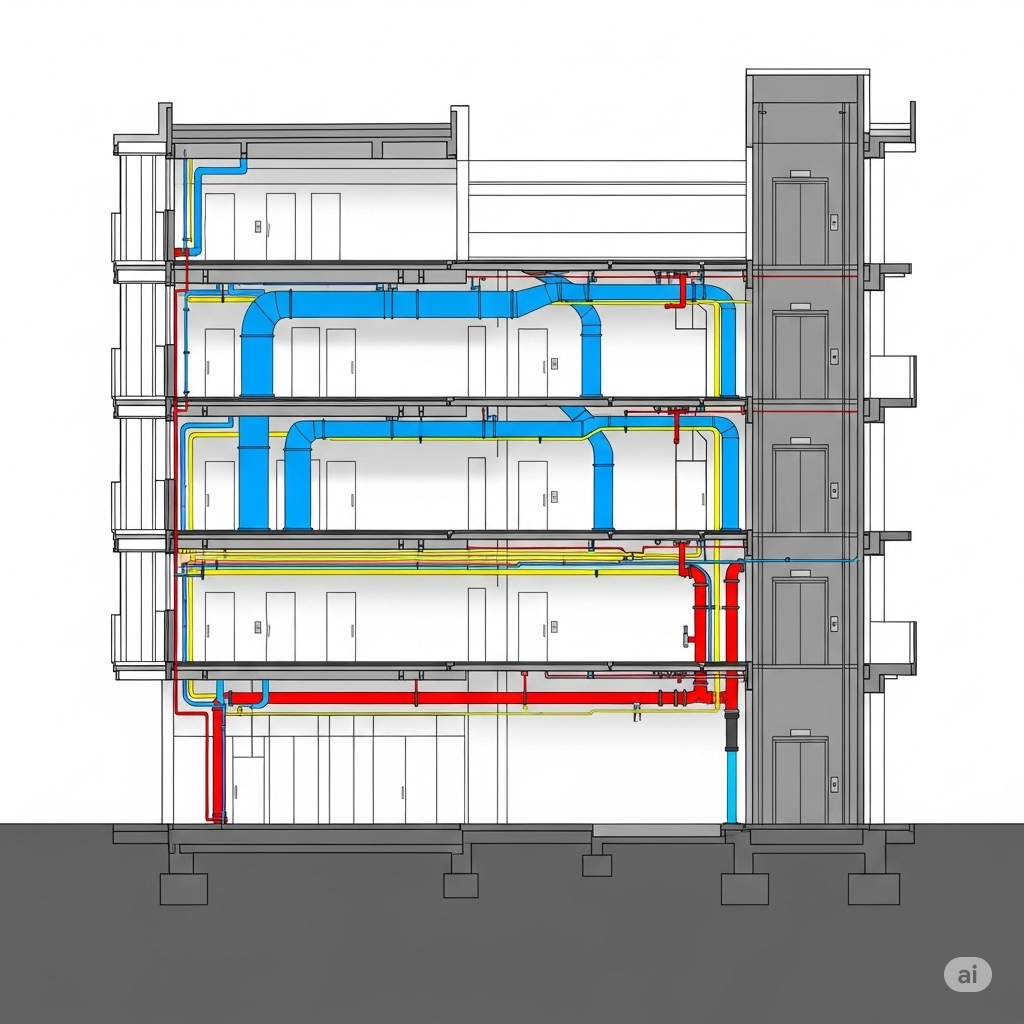

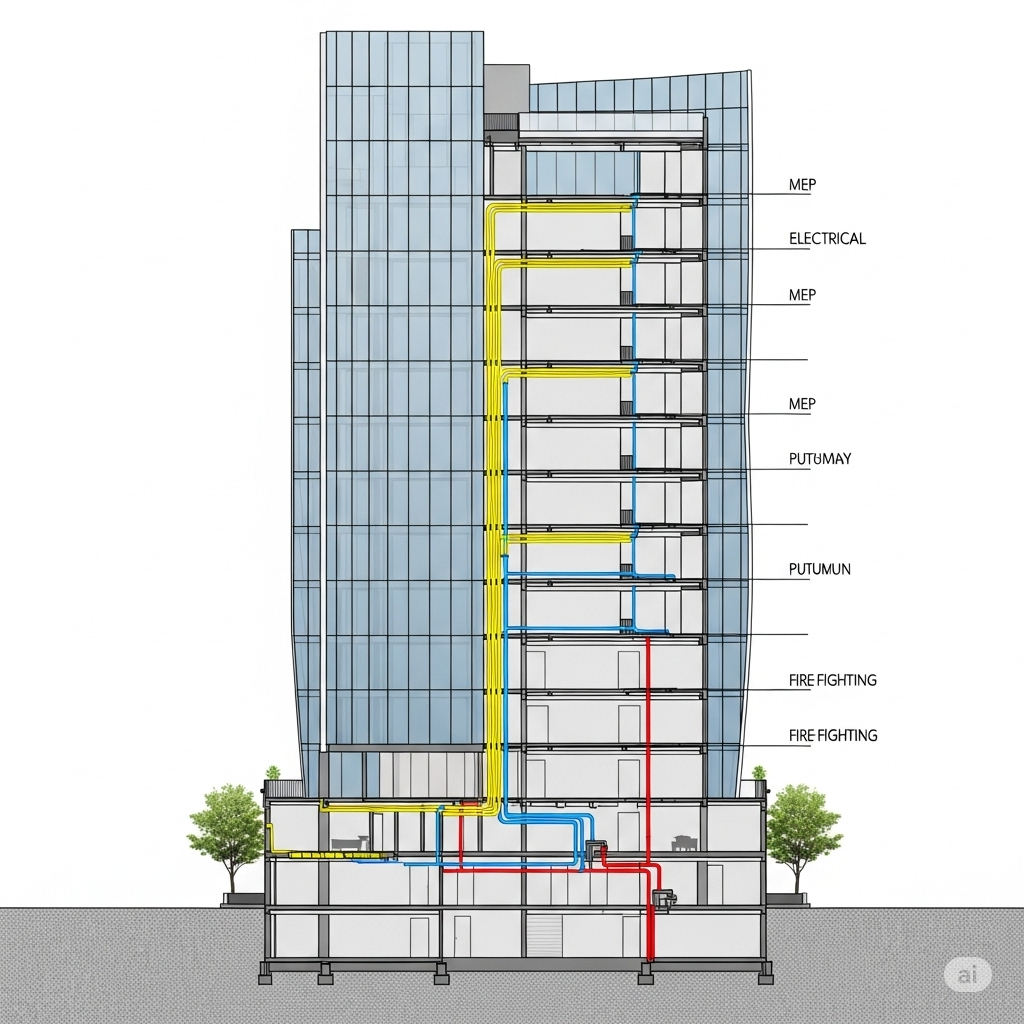

- Specialized technicians (electrical, HVAC, plumbing)

- General maintenance staff

- Administrative support

For a typical high-rise residential building (100 units), the maintenance team might include:

- 1 facility manager

- 2-3 specialized technicians (electrical, plumbing)

- 3-5 general maintenance staff

- 1 administrative coordinator

Typical Deliverables at Different Maintenance Stages

Post-construction maintenance involves various deliverables across different stages:

Initial Handover Stage

- Comprehensive building operation and maintenance manuals

- As-built drawings and specifications

- Warranty certificates and documentation

- Initial defect list and rectification plan

Routine Maintenance Stage

- Maintenance schedules and logs

- Inspection reports

- Work orders and completion certificates

- Performance metrics and dashboards

Major Maintenance/Renovation Stage

- Condition assessment reports

- Renovation/upgrade proposals

- Regulatory compliance documentation

- Cost-benefit analyses for major interventions

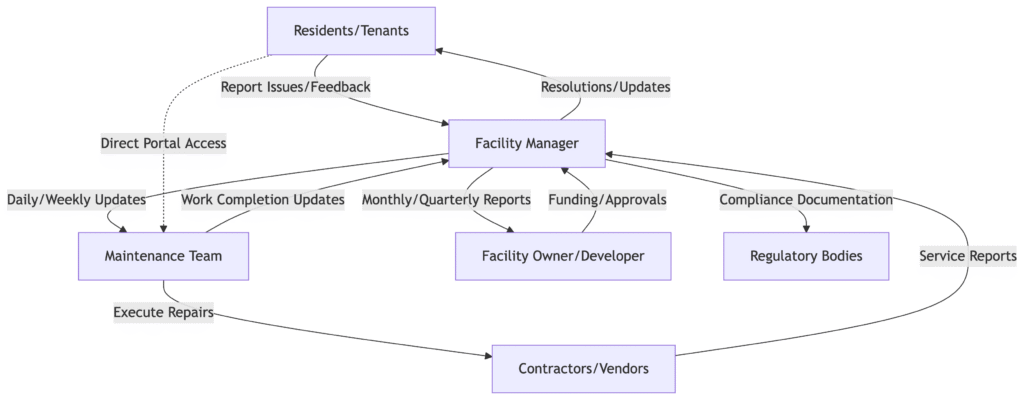

Key Stakeholders and Communication Protocols

Effective maintenance requires clear communication among various stakeholders:

Stakeholder Matrix

| Stakeholder | Role | Communication Frequency | Communication Medium |

|---|---|---|---|

| Facility Owner/Developer | Strategic decisions, funding approval | Monthly/Quarterly | Formal reports, meetings |

| Facility Manager | Oversee maintenance operations | Daily/Weekly | Digital platforms, meetings |

| Maintenance Team | Execute maintenance activities | Daily | Work orders, digital platforms |

| Residents/Tenants | Report issues, provide feedback | As needed | Dedicated portals, emails |

| Contractors/Vendors | Specialized maintenance services | As per contract | Formal communication |

| Regulatory Bodies | Compliance oversight | Periodic | Official documentation |

Communication Flow Chart

Relevant Standards and Guidelines

Post-construction maintenance in India is guided by several standards:

Indian Standards (IS)

- IS 15183:2002: Guidelines for maintenance management of buildings

- IS 1950:1962: Code of practice for sound insulation of non-industrial buildings

- IS 3935:1966: Code of practice for composite construction

- IS 4878:1986: Byelaws for construction of cinema buildings

International Standards

- ISO 55000: Asset management standards

- ISO 41001:2018: Facility management system standards

Industry Guidelines

- National Building Code of India (NBC) 2016 – Part 12: Asset and Facility Management

- RERA (Real Estate Regulatory Authority) guidelines for post-handover maintenance

Maintenance Checklist for Different Project Types

Residential Buildings (Monthly Inspection)

- Plumbing systems integrity check

- Electrical systems safety inspection

- Building exterior inspection for cracks/damage

- Roof and waterproofing inspection

- HVAC systems performance check

- Fire safety equipment inspection

- Elevator maintenance (for high-rises)

- Common area cleanliness assessment

- Pest control evaluation

- Water quality testing

Commercial Buildings (Weekly Inspection)

- HVAC performance and efficiency

- Building automation systems check

- Energy consumption monitoring

- Security systems verification

- Emergency systems testing

- Elevator and escalator safety check

- Parking facilities inspection

- Lighting systems assessment

- Occupant comfort evaluation

- Indoor air quality measurement

Industrial Facilities (Daily Monitoring)

- Production equipment integrity

- Utility systems performance

- Safety mechanisms verification

- Environmental compliance check

- Waste management systems

- Material handling equipment inspection

- Structural integrity assessment

- Fire safety systems testing

- Emergency response readiness

- Security perimeter inspection

The Feedback Loop: Improving Future Projects

Feedback Collection Methodologies

Effective feedback systems are crucial for continuous improvement:

- User Surveys: Structured questionnaires for occupants/users

- Defect Tracking Systems: Digital platforms to log and track issues

- Post-Occupancy Evaluations (POE): Formal assessments of building performance

- Smart Building Technologies: IoT sensors and systems providing real-time performance data

Implementing a Feedback System

A robust feedback system typically includes:

- Data Collection: Through surveys, direct communication, or automated systems

- Analysis: Identifying patterns and root causes

- Action Planning: Developing solutions for identified issues

- Implementation: Executing necessary changes

- Monitoring: Tracking the effectiveness of interventions

Feedback-Driven Design Basis Calculation Example

For a high-rise residential project, feedback from previous projects might indicate that the original HVAC system design was inadequate during peak summer months. Design engineers can use this data to recalculate cooling loads:

Revised Cooling Load = Original Design Load × (1 + Performance Gap Factor)

Where:

Performance Gap Factor = Average Temperature Deviation / Design Temperature Differential

Example:

If the original system maintained 28°C instead of the designed 24°C

when outdoor temperature was 40°C:

Performance Gap Factor = (28°C - 24°C) / (40°C - 24°C) = 4°C / 16°C = 0.25

Revised Cooling Load = Original Load × 1.25

This calculation demonstrates how feedback data directly influences future design decisions.

Value Engineering in Post-Construction Maintenance

Value engineering in the maintenance phase focuses on optimizing operational efficiency while maintaining or enhancing performance. Key opportunities include:

Energy Optimization

- Retrofitting LED lighting systems (30-50% energy savings)

- Installing occupancy sensors in common areas (15-20% energy savings)

- Upgrading to more efficient HVAC equipment (20-40% energy savings)

Resource Management

- Implementing rainwater harvesting systems

- Installing water-efficient fixtures

- Developing waste segregation and recycling programs

Operational Efficiencies

- Adopting preventive maintenance scheduling to reduce emergency repairs

- Implementing remote monitoring systems to reduce manual inspections

- Using data analytics to optimize maintenance scheduling

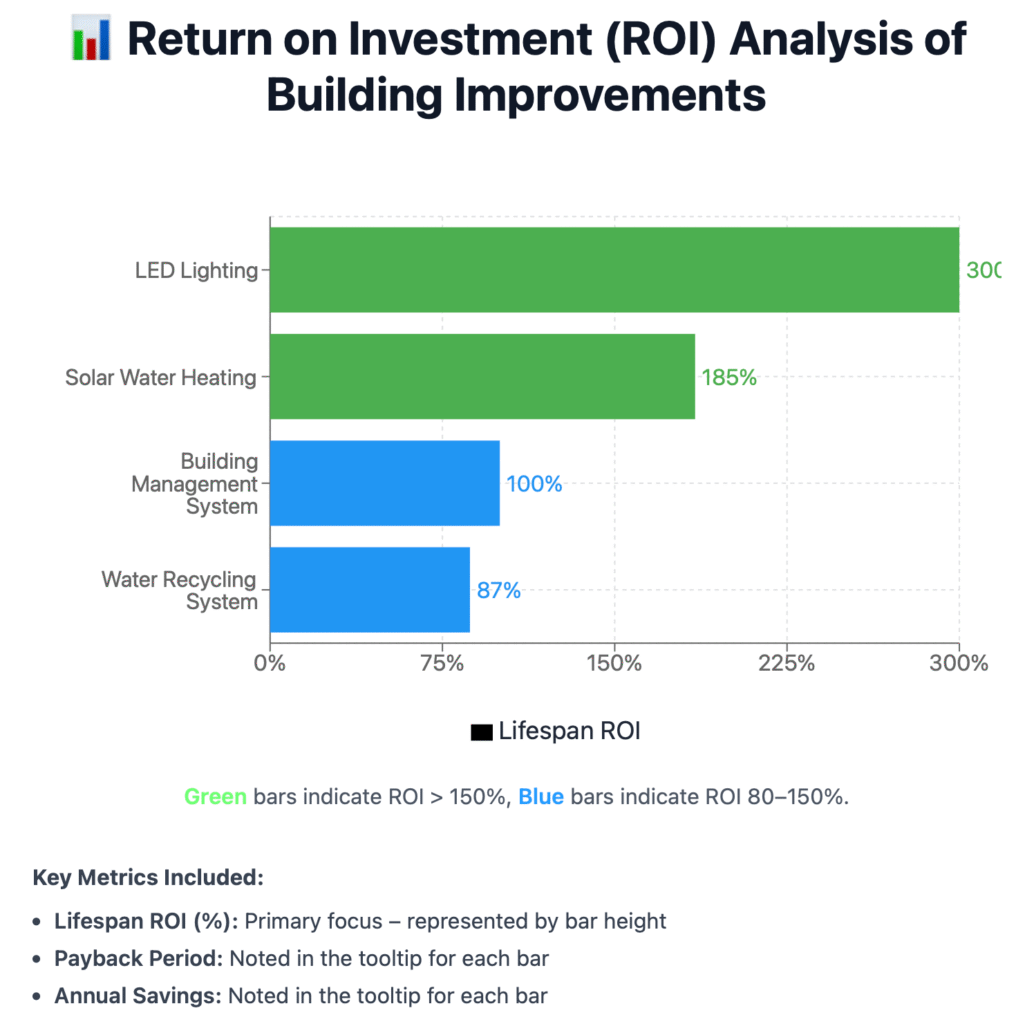

Cost-Benefit Analysis for Value Engineering Interventions

| Intervention | Initial Cost | Annual Savings | Payback Period | Lifespan ROI |

|---|---|---|---|---|

| LED Lighting | ₹2,00,000 | ₹80,000 | 2.5 years | 300% |

| Solar Water Heating | ₹3,50,000 | ₹1,00,000 | 3.5 years | 185% |

| Building Management System | ₹15,00,000 | ₹3,00,000 | 5 years | 100% |

| Water Recycling System | ₹8,00,000 | ₹1,50,000 | 5.3 years | 87% |

Case Study: Sunshine Towers, Pune

Project Overview

Sunshine Towers is a 250-unit residential high-rise in Pune, completed in 2018. After experiencing several maintenance challenges in its first year of operation, the management implemented a comprehensive maintenance and feedback system.

Challenges Identified

- Frequent elevator breakdowns

- Water seepage in basement parking

- High energy consumption

- Inadequate waste management system

- Poor response to resident complaints

Solutions Implemented

Proactive Maintenance Program:

- Shifted from reactive to preventive maintenance

- Implemented CMMS software for scheduling and tracking

- Established regular inspection protocols

Feedback System:

- Deployed a mobile app for residents to report issues

- Established response time standards (24 hours for minor issues, 4 hours for emergencies)

- Created a quarterly satisfaction survey

Value Engineering Initiatives:

- Installed a building management system

- Upgraded to energy-efficient lighting

- Implemented rainwater harvesting

- Established a waste segregation system

Results After Two Years

- 78% reduction in elevator downtime

- 95% resolution of water seepage issues

- 32% reduction in energy consumption

- 40% increase in waste recycling

- 88% improvement in resident satisfaction scores

Key Learnings

- Early investment in maintenance systems yields significant long-term savings

- Real-time feedback mechanisms dramatically improve response times

- Data-driven maintenance planning prevents major failures

- User satisfaction directly correlates with property value appreciation

Design Basis for Maintenance Planning

When establishing a maintenance plan, consider these fundamental calculations:

Maintenance Resource Allocation

For a residential property:

Maintenance Staff Requirement = (Built-Up Area in sqm / 3000) +

(Number of Units / 50) +

(Number of Specialized Systems / 5)

Maintenance Budget Calculation

Annual Maintenance Budget = Base Cost + Variable Cost

Where:

Base Cost = Built-Up Area × Base Maintenance Rate

Variable Cost = Additional Systems Cost + Age Factor Cost

Example for a 10,000 sqm high-rise:

Base Cost = 10,000 sqm × ₹50/sqm = ₹5,00,000

Variable Cost = ₹2,00,000 (systems) + ₹1,00,000 (age factor) = ₹3,00,000

Annual Budget = ₹8,00,000

Maintenance Frequency Planning

| Building Element | Inspection Frequency | Minor Maintenance | Major Maintenance |

|---|---|---|---|

| Structure | Annual | 2 years | 10 years |

| Plumbing | Quarterly | 6 months | 5 years |

| Electrical | Monthly | 3 months | 3 years |

| HVAC | Monthly | 3 months | 5 years |

| Fire Safety | Monthly | 6 months | 2 years |

| Elevators | Fortnightly | Monthly | Annual |

| Waterproofing | Bi-annual | 1 year | 5 years |

Conclusion

Post-construction maintenance and feedback represent vital components of the project lifecycle that often determine the true success of a construction project. In India’s rapidly developing built environment, adopting systematic maintenance practices and robust feedback mechanisms can significantly enhance building performance, extend asset life, and improve user satisfaction.

For developers, facility managers, and homeowners alike, investing in proper maintenance and feedback systems isn’t merely an operational necessity—it’s a strategic investment that yields substantial returns through reduced lifecycle costs, enhanced property values, and improved quality of life for occupants.

By embracing the methodologies, standards, and value engineering opportunities outlined in this blog, stakeholders can ensure their projects don’t just survive but thrive long after the construction phase has ended.